Overhead line insulators play a vital role in ensuring the safety and stability of electrical transmission systems. This article delves into the various types of insulators, their applications, and key selection criteria for optimal performance.

Table of Contents

What are Overhead Line Insulators?

Insulators are crucial components in electrical systems, as they prevent the flow of electric current between conductors and the ground or other conductive surfaces. In overhead power lines, they support conductors and maintain their separation while resisting electrical, mechanical, and environmental stresses.

Types of Overhead Line Insulators

There are various types of insulators used in overhead power lines, each with distinct characteristics and applications.

1. Pin Type Insulators

Pin insulators are the most basic and oldest type of insulators, typically used for low-voltage applications. They consist of a single piece of porcelain or glass, mounted on a pin that is fixed to the cross-arm of the supporting structure.

Applications:

- Distribution lines (up to 33 kV)

- Telecommunication lines

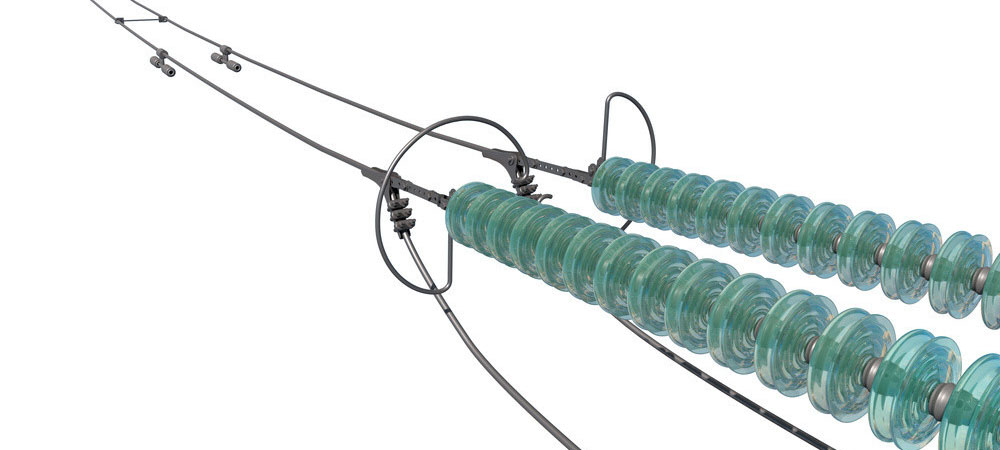

2. Suspension Insulators

Suspension insulators consist of a series of porcelain or glass units connected by metal links. They are designed for higher voltage levels, providing better mechanical strength and flexibility compared to pin type insulators.

Applications:

- High voltage transmission lines (66 kV and above)

- Extra-high voltage (EHV) and ultra-high voltage (UHV) lines

3. Strain Insulators

Strain insulators are used to manage mechanical stresses in transmission lines, particularly at sharp bends, angles, and dead ends. They are typically made of porcelain or glass units, arranged in a string configuration.

Applications:

- Anchor towers

- Tension towers

- Dead-end towers

4. Shackle Insulators

Shackle insulators, also known as a spool or guy strain insulators, are used for low-voltage distribution lines. They are mounted horizontally and can be arranged in a straight line or as a strain insulator to provide mechanical support.

Applications:

- Low voltage distribution lines

- Guy wires

5. Post Insulators

Post insulators are designed for higher voltage applications, offering better insulation and mechanical strength compared to pin insulators. They can be either porcelain or polymer, and are mounted on a supporting structure.

Applications:

- Substations

- Switchyards

- Circuit breakers

Materials Used in Overhead Line Insulators

Some common materials used for manufacturing insulators include:

1. Porcelain

Porcelain is a widely-used insulating material, known for its excellent dielectric properties and mechanical strength. It is produced by heating a mixture of clay, kaolin, feldspar, and other minerals at high temperatures, resulting in a dense, glassy, and non-porous material.

Advantages:

- High electrical resistance and dielectric strength

- Good mechanical strength and durability

- Resistance to corrosion and environmental factors

Disadvantages:

- Brittle and prone to breakage under excessive mechanical stress

- Heavier than other insulating materials, which may increase the weight of the supporting structure

2. Glass

Glass insulators are made from toughened or tempered glass, which undergoes a thermal treatment process to improve its strength and durability. This material has been used for insulators since the 19th century, offering several benefits over porcelain.

Advantages:

- High electrical resistance and dielectric strength

- Good mechanical strength and durability

- Transparency, allowing for easy visual inspection of the insulator’s condition

Disadvantages:

- Susceptible to surface damage, which may reduce its electrical resistance

- Heavier than polymer insulators

3. Polymer (Silicone Rubber)

Polymer insulators, made from silicone rubber or other elastomeric materials, are a modern alternative to traditional porcelain and glass insulators. These insulators consist of a fiberglass core covered by a weather-resistant polymer housing.

Advantages:

- High electrical resistance and dielectric strength

- Lightweight, making them easier to transport and install

- Excellent resistance to environmental factors, including UV radiation, pollution, and temperature variations

- High flexibility, allowing them to withstand mechanical stresses without breaking

Disadvantages:

- Susceptible to aging and degradation, which may reduce their lifespan compared to porcelain and glass insulators

- Higher initial cost compared to traditional insulating materials

Key Selection Criteria for Insulators

When selecting insulators for overhead power lines, consider the following factors:

- Voltage level: Insulators must be designed to withstand the voltage level of the transmission line.

- Mechanical strength: Insulators should have adequate mechanical strength to support conductors and resist environmental stresses.

- Insulation properties: Insulators must provide sufficient electrical insulation to prevent flashovers and punctures.

- Environmental factors: Insulators should be resistant to pollution, UV radiation, and temperature variations.

- Cost and maintenance: The chosen insulator should be cost-effective and require minimal maintenance.

Why Choose Powertelcom as Your Insulator Manufacturer

Powertelcom is a professional insulator manufacturer, offering high-quality insulators with exceptional durability and performance. We provide a wide range of insulator types, catering to various voltage levels and applications. Our insulators are designed to withstand harsh environmental conditions, ensuring reliable operation and minimal maintenance.

Unique Selling Points and Advantages

- High-quality insulators for a wide range of voltage levels and applications

- Exceptional durability and performance under harsh environmental conditions

- Cost-effective solutions with minimal maintenance requirements

- Professional expertise in insulator manufacturing

FAQs

What is the primary purpose of insulators in overhead power lines?

Insulators in overhead power lines prevent the flow of electric current between conductors and the ground or other conductive surfaces, ensuring safety and stability in electrical transmission systems.

What are the main types of insulators used in overhead power lines?

The main types of insulators used in overhead power lines include pin type, suspension, strain, shackle, and post insulators. Each type is designed for specific voltage levels and applications.

How are the materials chosen for manufacturing insulators?

Insulators are typically made from materials with high electrical resistance and good mechanical strength, such as porcelain, glass, and polymer (silicone rubber).

What factors should be considered when selecting insulators for overhead power lines?

Key factors to consider when selecting insulators include voltage level, mechanical strength, insulation properties, environmental factors, and cost and maintenance requirements.

Why choose Powertelcom as an insulator manufacturer?

Powertelcom is a professional insulator manufacturer offering high-quality insulators with exceptional durability, performance, and cost-effectiveness. Our insulators are designed for various voltage levels and applications, ensuring reliable operation and minimal maintenance.