Secondary Rack

Secondary rack is a type of insulator cable support with a steel U channel at the base. The base is adjoined with the utility pole through nuts and bolts. The secondary rack has a galvanized finish, and it follows the ASTM-123 standard. the secondary rack is designed in such a manner that it can support three to four conductors.

The question arises: Why is a secondary rack important? The answer lies in optimum performance and efficiency when it comes to the construction of an overhead infrastructure for which quality accessories and materials are needed. In such cases, a good quality secondary rack comes quite handy. Consequently, whenever it comes to pole line infrastructures, a secondary rack has a huge importance. Whether it is a matter of utility pole mounting, telephone pole line, or any other necessary infrastructure, good quality secondary racks always make them better at functionality.

The manufacturing steps involve welding, drilling, riveting, and hot dip galvanizing. Our experts make sure that our secondary racks get manufactured with the best techniques and technologies involved in the process to ensure the best quality, functionality, reliability, and longevity, which is highly critical when it comes to telecommunication logistics and equipment.

| SECONDARY RACK, HEAVY DUTY (EXTENDED BACK) | |||||

| Stock No. | No.Of Wire (mm) | Wire Spacing (mm) | Length (mm) | Approximate Ship Weight kg. /100 Pcs. | Standard Pkg. Qty. / Carton |

| F0320-H3 | 3 | 200 | 605 | 360.00 | 5 |

| F0320-H2 | 2 | 200 | 450 | 204.00 | 5 |

| SECONDARY RACK, MEDIUM DUTY | |||||

| F0321-M3 | 3 | 200 | 524 | 250.00 | 5 |

| F0321-M2 | 2 | 200 | 340 | 160.00 | 5 |

| SECONDARY RACK, LIGHT DUTY | |||||

| F0321-L3 | 3 | 200 | 524 | 250.00 | 5 |

| F0321-L2 | 2 | 200 | 340 | 160.00 | 5 |

Secondary Rack Complete Buying Guide

secondary rack with spool insulator

Are you dealing with electrical power distribution systems? One of the power line accessories that you should consider buying is the secondary rack.

In this guide, you are going to learn important facts about the secondary rack. At the end of it all, you will be in a position to buy the best secondary rack for power line in China.

What is a Secondary Rack?

A secondary rack is a U-shaped spool insulator cable that features steel at the base. The design of the insulator allows it to provide support either at the side or inside the power line pole.

The rack has mounting holes so that it is attached to the pole with the help of nuts and bolts. This ensures that they are properly secured to the poles. It is also easy to install such secondary racks since the process is not labor-intensive.

Most secondary racks in the market are capable of supporting up to four conductors. However, you should confirm with your secondary manufacturer’s specification so as not to overload the device.

Secondary rack insulators are usually installed at strategic points where power is to be distributed from the mainline to other subsidiary lines.

The support that the secondary racks give to the conductors prevent cases of sagging since they tend to tighten the conductors against the pole.

Components of a Secondary Rack

To give you a better understanding of what you are about to buy, here are the key components of a secondary rack:

Parts of a secondary rack

-Base: The base forms the bottom-end of a secondary rack. It is the part of the rack that holds onto the pole line or post to support other subsidiary components.

The base part is made of steel metal as it can withstand physical force and at the same time corrosion.

-U-channel: This component acts as the arm of the secondary insulator rack. It provides a platform for stringing the insulators of the powerline.

-Bolts and nuts: These are considered as accessories of the electrical spool holder as they make it easy for you to attach the rack to the pole line.

The guarantee the stability of the secondary rack.

-Holes: These are openings through which bolts and nuts will attach the secondary rack to the pole.

-Insulator: This part performs the primary function of secondary nut-to support the conductors. Insulators also regulate the flow of electric current.

-Cotton pin: The pin is used for fastening both ends of the U-channel.

-Clevis pin/fastener: This is a fastening component that features a clevis pin and a tang. It also plays a supporting role.

Types of Secondary Racks

There are different designs and configurations of secondary racks. This helps them to deal with different power needs.

Apart from design and configurations, there are different secondary rack sizes

Here are the types and configurations of secondary racks that you should know:

-Secondary rack 1 spool: As the name suggests, this type of secondary rack has one spool. A spool is a cylindrical part that an axial hole and a ridge.

Secondary rack 1 spool

1 spool rack is mainly used for telecommunication lines where you don’t have to support many conductors.

-Secondary rack 2 spool: This configuration is characterized by double spools. This allows it to effectively support parallel conductors.

Secondary rack 2 spool

-Secondary rack 3 spool: Like others, this secondary rack type has three spools.

-Secondary rack 4 spool: The rack has four spools hence is capable of supporting up to four conductors.

Applications of Secondary Racks

Based on their functions, secondary racks are useful in infrastructures that have poles and transmission cables.

These infrastructures include transmission lines, utility pole mountings, and telephone lines.

Although these are different infrastructures, there is one feature that is common in all of them.

There is a pole and there are cables that are connected from one pole to another.

It is also imperative to note that these projects are carried out globally. So, you can buy secondary racks in the Philippines, secondary racks in Africa, the Americas, or any other part of the world.

All you need is to know the scope of your project then buy the right secondary racks.

Steps for Installing a Secondary Rack

Whether you are into technical matters or not, it is vital to understand the process of installing secondary racks.

The process of secondary rack installation starts with marking the exact spots where the rack will rest.

After marking the spots, drill holes. Ensure that the sizes of the holes match with the specifications of the bolts and nuts.

Position the secondary rack over the drilled holes then tighten it using nuts and bolts. At this point, you can go ahead to add other components of the rack until it is complete and functional.

Test the stability of the secondary rack on the pole and rectify any mistakes.

That is it! Nothing complex. You only need to adhere to the pole line safety measures when installing a secondary rack.

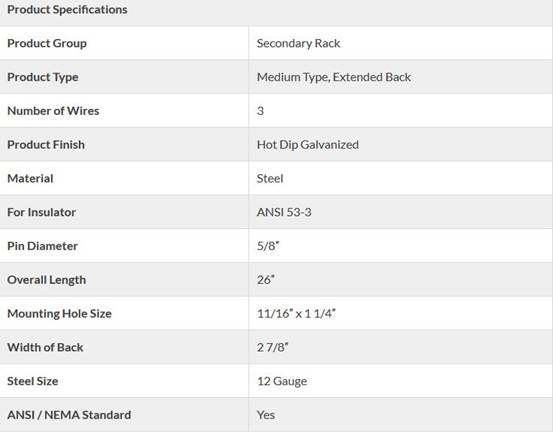

Secondary Racks Technical Specifications

Would you like to end up with the right secondary racks? It is vital that you take note of every detail of this electrical spool holder.

The technical specifications will determine whether the rack is the right one for your project and whether it will execute its job perfectly.

The table below has a sample of the technical specifications.

Technical specifications of a secondary rack

One of the critical specifications is material. Ensure that the rack is made of steel metal.

Another specification is the dimension. You should know the overall length, hole diameter, size of bolts, size of pin among others.

Do not hesitate to inquire about the secondary rack quality standard and certification. These specifications show that the

Secondary Rack Manufacturers and Suppliers

Looking for reliable secondary rack suppliers Philippines, Brazil, Kenya, Brazil, or any other parts of the world? We have the answers to what you are looking for.

secondary rack in the factory

We at Powertelcom design, manufacture, and supply quality secondary racks. We are a reputable secondary rack insulator manufacturer in China.

Whether you would like to buy secondary racks online or you want to visit us, start by contacting us. We will guide you until you receive these overhead pole line accessories.

FAQ

What is a secondary rack?

A secondary rack is a U-shaped spool insulator cable that features steel at the base. The design of the insulator allows it to provide support either at the side or inside the power line pole.

What are the types of secondary racks?

There are different designs and configurations of secondary racks.

- Secondary rack 1 spool

- Secondary rack 2 spool

- Secondary rack 3 spool

- Secondary rack 4 spool

The secondary rack can also be customized.

What is the application of the secondary rack?

Secondary racks are useful in infrastructures that have poles and transmission cables.

These infrastructures include transmission lines, utility pole mountings, and telephone lines.

5 tips when choosing a Secondary rack manufacturer.

- Price is extremely important, but it shouldn't be your sole criterion for choosing a partner.

- Know the quality assurance steps they take, and Check the quality of the products in stock.

- Good customer service is the premise of offering fast and convenient support.

- Make sure the production capacity of the manufacturer is enough and they can deliver on time.

- Schedule a factory visit for field inspection if you have the budget.