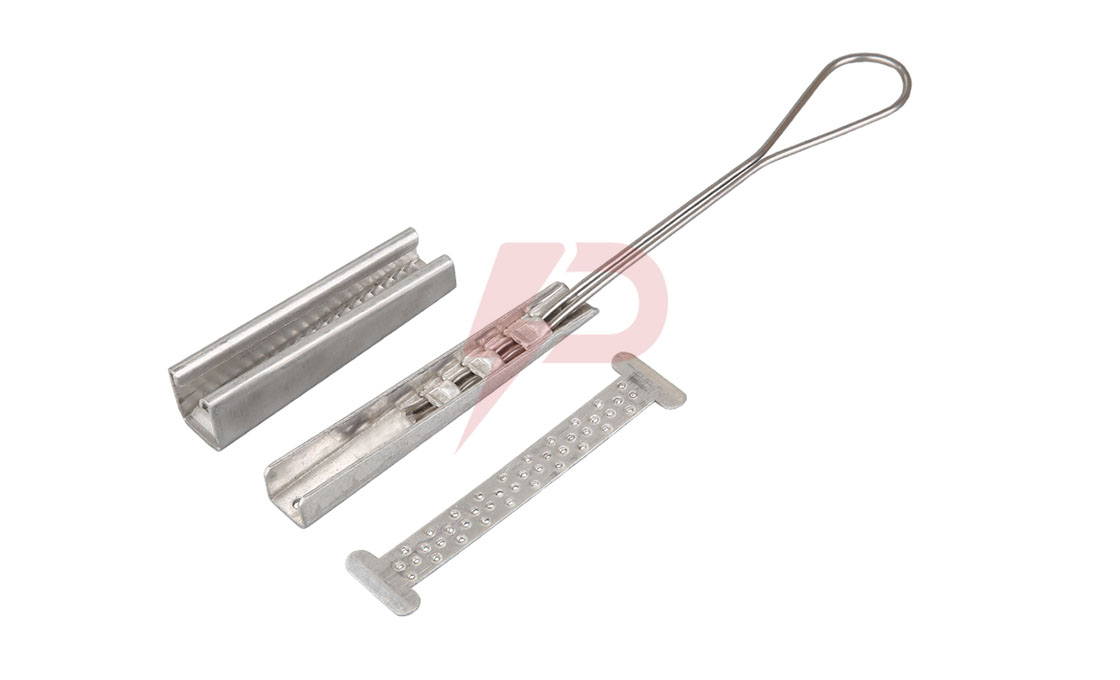

Downlead Clamp

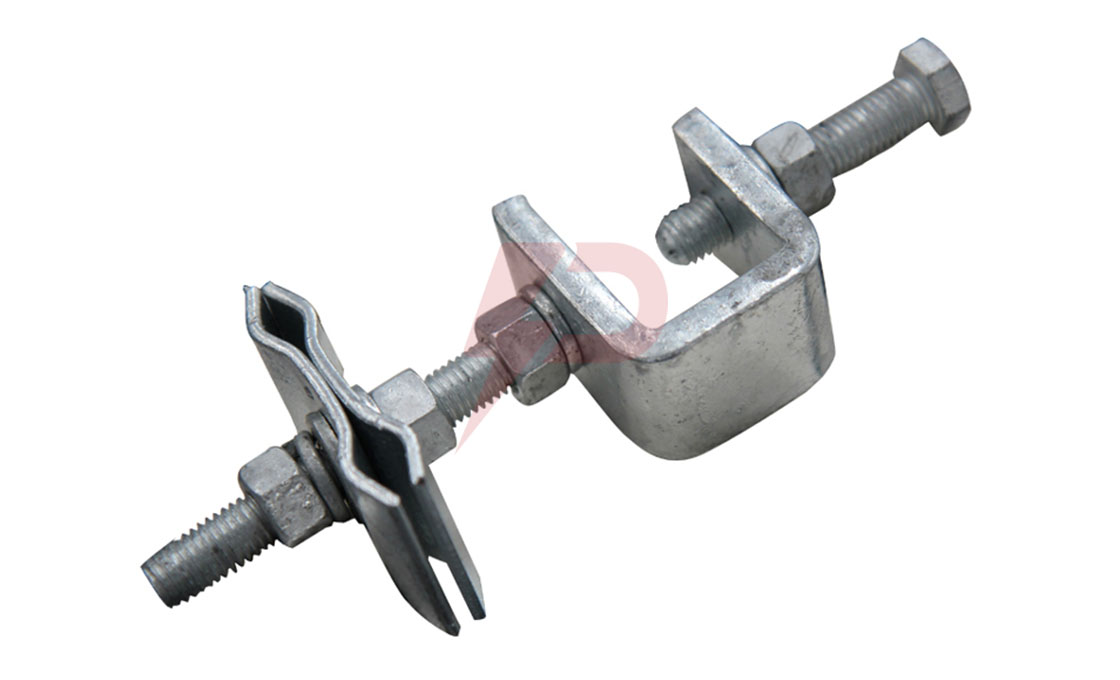

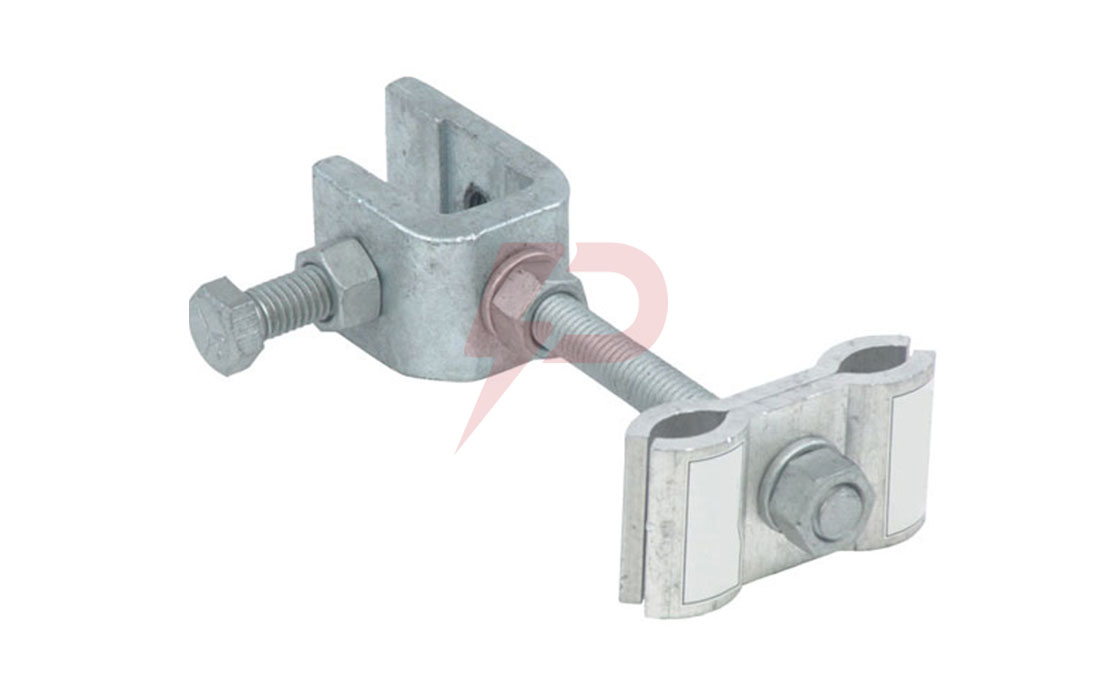

The downlead clamps support the OPGW (optical ground wires) from the upper part of the tower to the splice box. With proper installation of the downlead clamps, it offers sufficient strength and spacing without destroying the cable.

The clamp can establish a massive cable range owing to its exceptional design feature. This ensures it lowers the stocking requirement of the client when handling enormous cable diameters. The adapters in steel tower clamps ensure there is no drilling.

The clamp comprises four attachment portions that boost versatility when dealing with lattice towers, steel poles or wood. Also, the device has a 6-8 feet normal spacing. For the application of OPGW or ADSS, all urethane products can be used for flat or curved pole surfaces.

Features

- High resistance due to the weather-resistant urethane, but even pliable to support and protect the ADSS cables.

- Slip strength exceeds 100 lbs.

- Lattice adapters have break-away bolts for installation that offer precise torque

- It is designed as an all urethane and aluminium alloy product for the application of ADSS or OPGW.

- There is the inclusion of mounting accessories in a container with the addition of the recommended suffix code

- Availability of banding adapters

Model | Structure type | available cable diameter (mm) | Quality (kg) | Remark |

OYDZ-0100 | hot-dip galvanizing | 6.9-10.0 | 0.8 | Tower used |

OYDZ-0130 | hot-dip galvanizing | 10.1-13.0 | 0.8 | Tower used |

OYDZ-0160 | hot-dip galvanizing | 13.1-16.0 | 0.8 | Tower used |

OYDZ-0190 | hot-dip galvanizing | 16.1-19.0 | 0.8 | Tower used |

OYDZ-0220 | hot-dip galvanizing | 19.1-22.0 | 0.8 | Tower used |

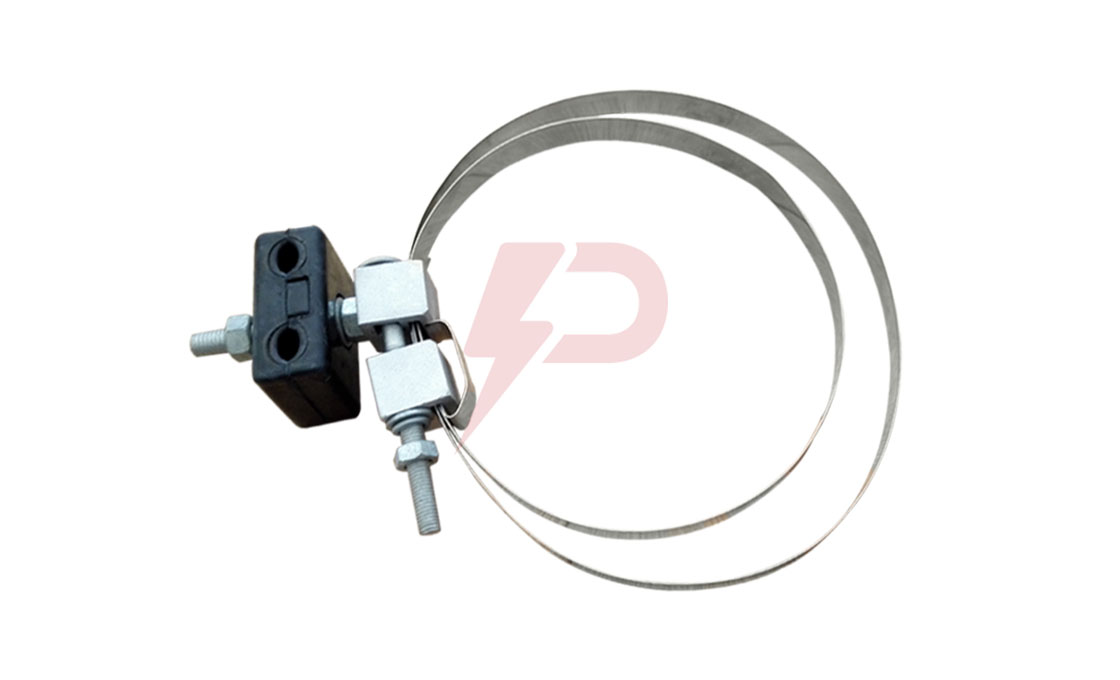

OYGD-0100 | Steel Strip | 6.9-10.0 | 0.55 | Pole used |

OYGD-0130 | Steel Strip | 10.1-13.0 | 0.55 | Pole used |

OYGD-0160 | Steel Strip | 13.1-16.0 | 0.55 | Pole used |

OYGD-0190 | Steel Strip | 16.1-19.0 | 0.55 | Pole used |

OYGD-0220 | Steel Strip | 19.1-22.0 | 0.55 | Pole used |

The Complete Guide to Downlead Clamp

The downlead clamp is used to tighten all-dielectric self-supporting (ADSS), and optical ground wire (OPGW) cables to structures while reducing clamping compressive forces that could damage the optical elements.

What is Downlead Clamp?

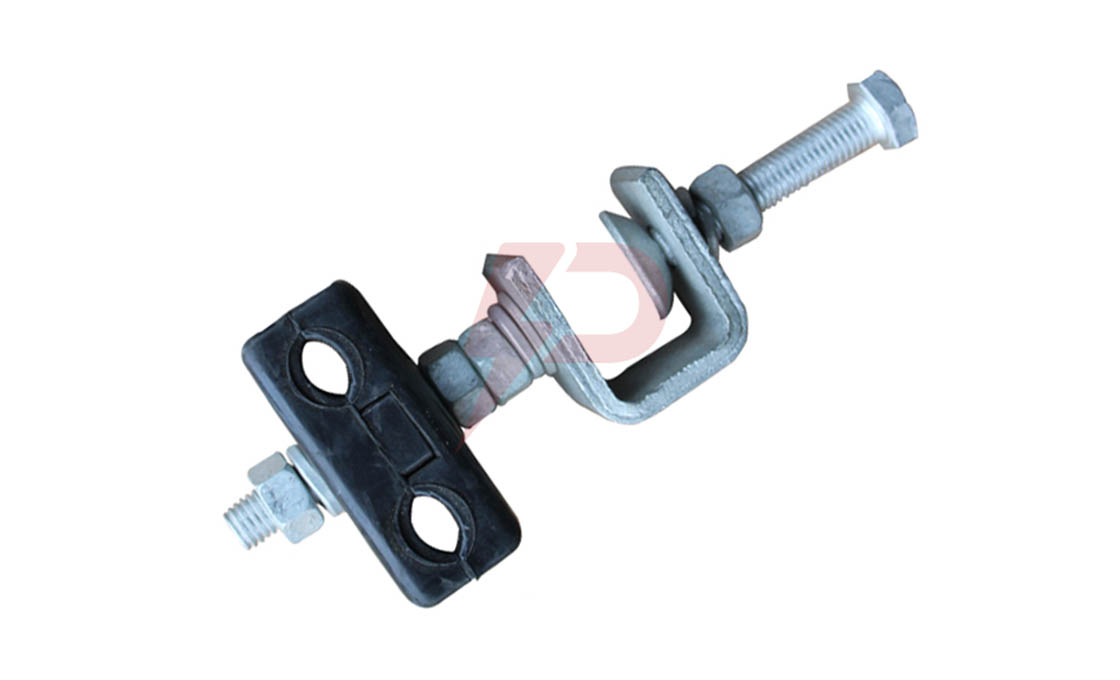

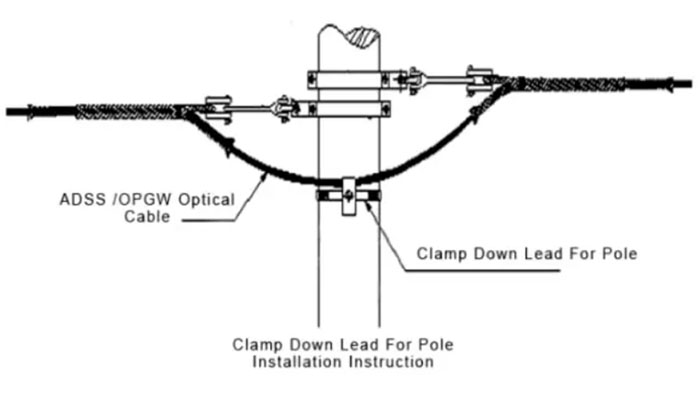

A downlead clamp or cushion is a pole hardware fitting used in telecommunication and electrical systems. The downlead cushion is fixed in a strain tower or pole to support the optical cables that move up and down.

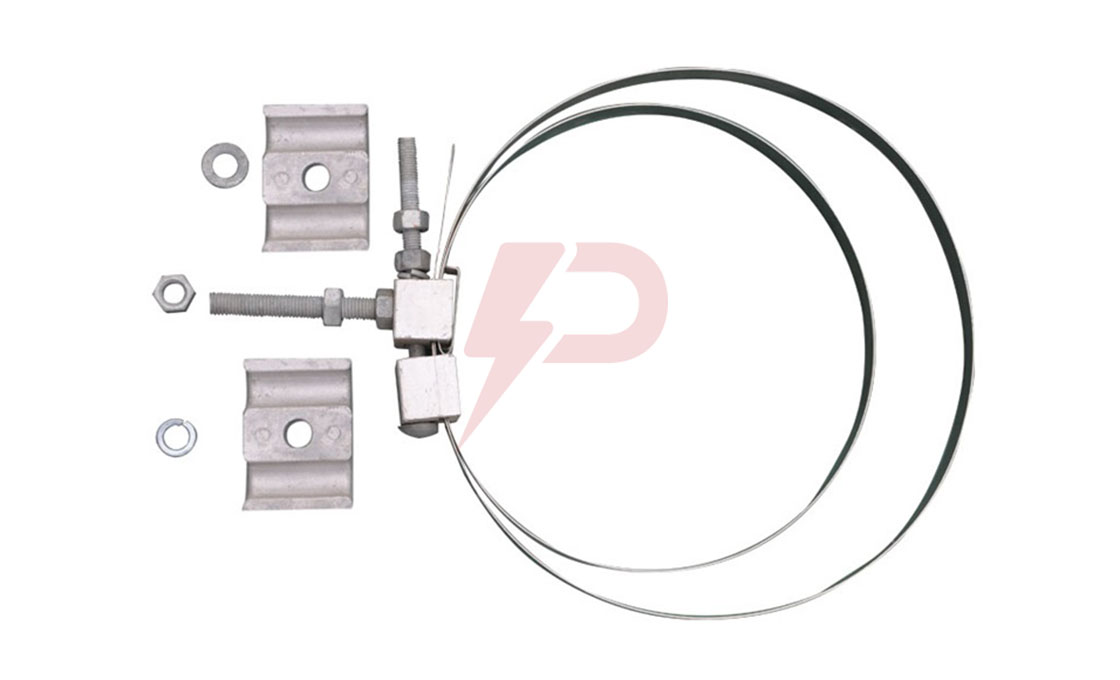

There are various downlead clamps, including downlead clamp for the optical ground wire, downlead clamp for all-dielectric self-supporting cables and downlead clamp for tower and pole. Downlead clamp for towers is made of rubber and a stainless steel band. The rubber band protects the optical fibre, and it is fixed to a pole by a stainless steel band. This ensures the optical fibre is firm to minimize wear due to friction.

What is the Function of the Downlead Clamp?

The downlead clamp is utilized in guiding cables from the top of a pole to the bottom. It could be securing fibre optic cables on a tower to the splice box. Downlead clamp is in various designs and shapes which can support enormous cables. The design of the downlead clamp provides a slip strength. Adapters are fixed to steel tower clamp to eradicate drilling problems. Therefore, it becomes easy and simple during installation.

The downlead clamp for poles is made of steel banding. This clamp ensures OPGW and ADSS cables are guided from the pole and tightly fixed to curb abrasion.

The downlead clamp for the tower is hot-deep galvanized to support the movement of ADSS or OPGW cables. This clamp ensures cables are tightly held to inhibit damages.

The downlead clamps for OPGW and ADSS are made of rubber to support the all-dielectric self-supporting and optical ground wire cables.

Components of a downlead clamp

The main components of the downlead clamp include;

Steel Bracket

The steel bracket is located at the lower part of the downlead clamp. It ensures all cables are securely locked to prevent them from dropping after installation.

Hex Head Bolt

The Hex bolt is M16 by 140mm. The bolt locks the optical cables on poles and towers. The bolt needs to be well tightened to support the installation process.

Hex Nut

This is an M16 nut. The hex nut ensures the downlead clamp is installed correctly.

Rubber part

The rubber prevents abrasions on optical cables.

There has to be a proper tightening of the bolts and nuts to provide a rubber part’s firm grip.

C-clamp

Square washer- 2-inch square

Lock washer –M16

Downlead cushion kit

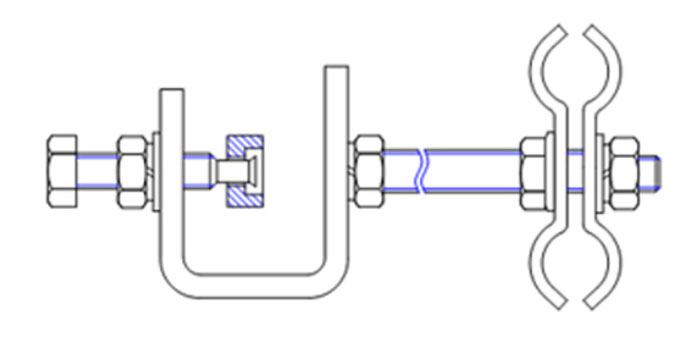

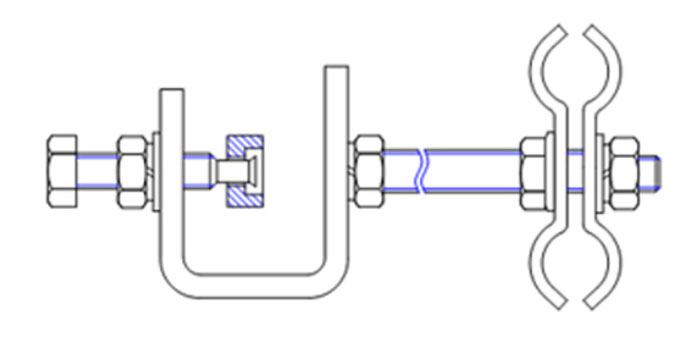

How to install a downlead clamp?

- All parts to be pre-assembled loosely in a flush mount or extended mount configuration.

- Push the C-clamp into the leg of the tower. The C-clamp can support tower legs with a maximum thickness of 29mm.

- The bolt should be tightened to ensure the C-clamp is mounted onto the legs of the tower.

- The OPGW or ADSS cables should be slipped carefully into the grooves of the downlead clamp.

- Nuts are tightened against the clamp until the square and lock washers are all flat. Ensure the bolts are tightened against the tower.

- For extended mount configuration, the remaining nuts have to be tightened against the clamp to have a flat lock washer. A wrench should tightly hold the bolt head.

- The lattice tower clamps should be placed along with the structure at 1.2 to 1.8 meters apart.

Features of the downlead clamp

- Ability to take a wide conductor range

- Full protection of optical fibres.

- Availability of banding adapters

- High slip strength that exceeds 100lbs.

- High torque precision due to the break-away bolts of lattice adapters.

- A guide pin reduces installation issues, and optical ground wires are protected by lining up on the clamp during tightening.

- A device to inhibit rotation in a lattice tower clamp. This supports single installation and clamp locking to the tower.

- Three-part numbers are sufficient to support optical cables of 25” to 1.00.”

- Banding adaptors ensure there no drilling into poles

- Lattice tower adaptors have one part that covers the entire thickness of tower steel.

- High resistance due to the weather-resistant urethane, but even pliable to support and protect the ADSS or OPGW cables.

Accessories used with a downlead clamp

- The hardware wood pole kit consists of the square washer, round washer, and ½” by 4” lag screw.

- The banding bracket of limited tension consists of lock washer, hex nut, banding bracket, square washer and a long head hex bolt.

- Lattice tower clamp with a six-inch-long bolt, a clamp with 10” long bolt and an 8” long bolt.

- The UNC hex bolt kit with the flat washer, lock washer, hex nut and 1/2 to 13 by 3” hex bolt.

Summary

The downlead clamp will ensure the securing of OPGW and ADSS cables on towers or poles. It is a vital pole line hardware that facilitates effective transmission of electricity and telecommunication signals.