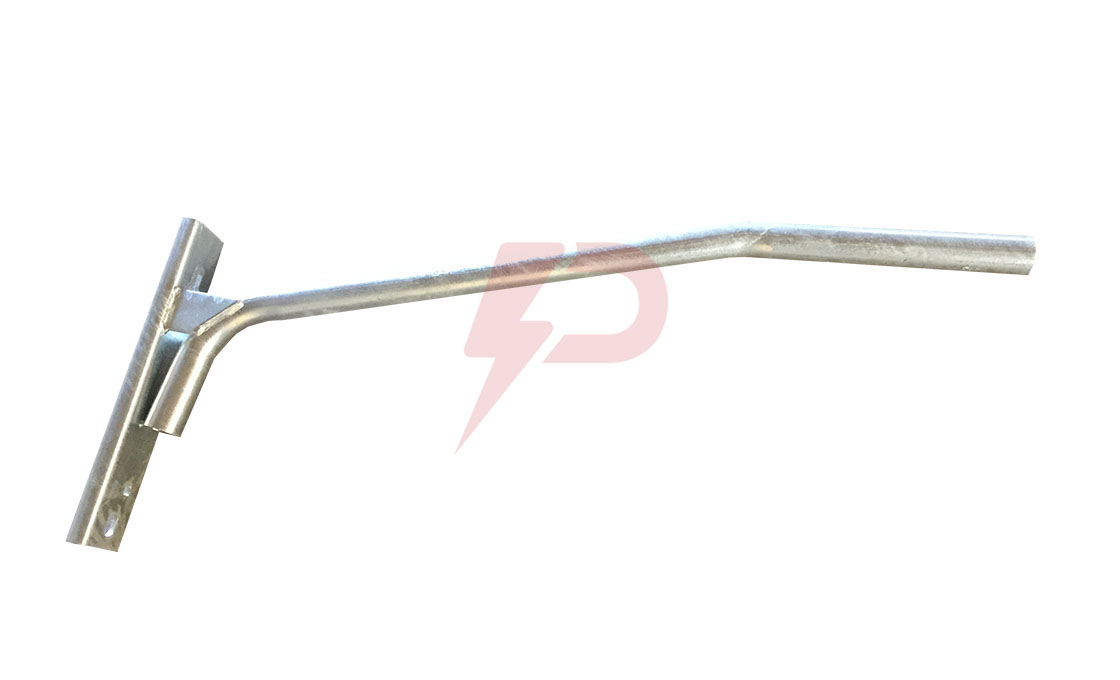

Street Light Arm

Found on the light poles or street light, a street light arm is an extension of the structure that extends towards the LED end. Broadly speaking, a street light arm is used to amplify the magnitude of the light projecting from the pole for a better view.

The street light arm is also known through a lot of other terms, some of which are used in the technical field while some are used more commonly in a specific area:

- Street light bracket arm

- Street light mounting arm

- Light pole arm bracket

- Street light mounting brackets

- Light mounting bracket

A street light arm is strategically important for enhancing lighting in residential areas, pedestrian crossings, and urban settings. The right features, design, assemblage, and materials are essential as they decide the durability and effectiveness of the product.

Features

The street light arm manufactured is able to withstand the torque effect on applying a weight of 75 kilograms with a distance of 1.5 m from the site where the luminaire is fixed. This is taken as an example to describe the torque effect.

A street light arm with high tensile strength is resistant to corrosive weather conditions and other situations.

For avoiding damages, any sharp edges of the structure are made smooth by the process of polishing.

For fastening the street light arm that is subjected to delivery, manufacturers use a strap made of either plastic or metal to secure the product to the platform.

The cable port or the entry holes of the street light arm are kept round so no cable entering to the port is susceptible to abrasion.

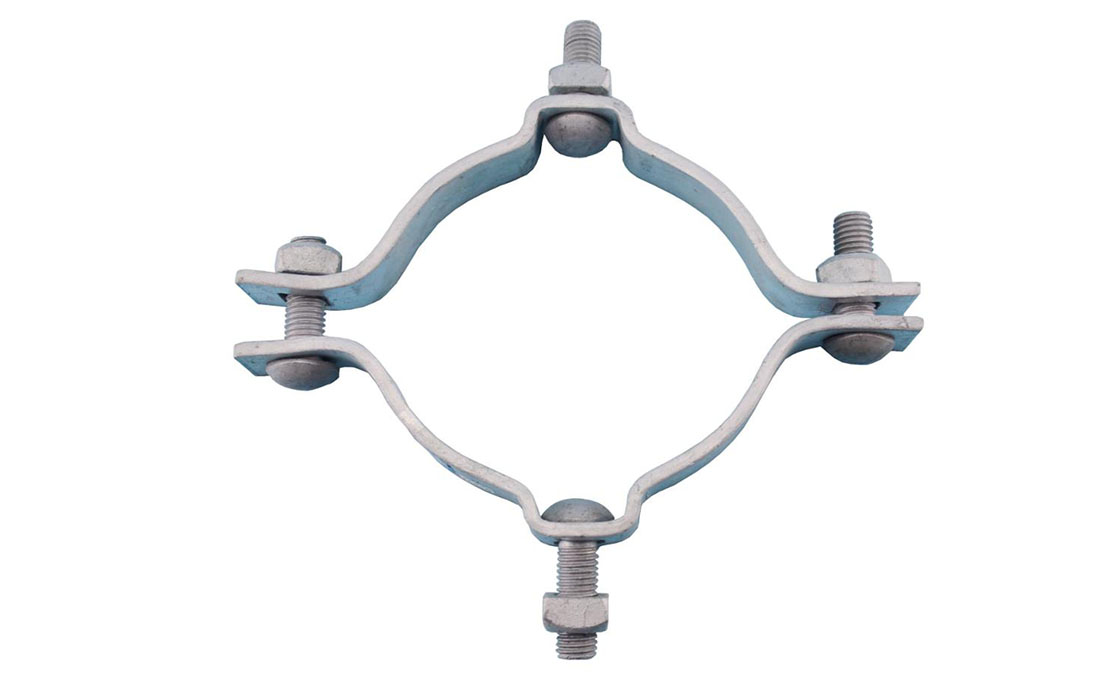

The street light arm needs to have compatible fixing joints and parts with the light pole. In addition, the manufacturers of the street light arm can directly supply the light mounting bracket for on-site fixation.

Street Light Arm – The Complete Guide

The street light arm is widely used on types of the street light pole, such as the wood pole and steel pole. What the function of the street light arm and why is it so widely used.

- 1. What is a street light arm?

- 2. What is the function of street light arms?

- 3. What are the main parts of a street light arm?

- 4. How to use a street light arm?

- 5. Types of street light arms

- 6. Why street light arm is important?

- 7. How to manufacture a street light arm?

- 8. What is the process of galvanizing the street light arm?

- 9. Street light arm bracket specifications and features

- 10. Testing of the street light arm bracket

- 11. Packaging and delivery of street light arm

- 12. Frequently asked questions?(FAQs)

What is a street light arm?

Street light arms are widely used outside the streets present on street light poles, they are one type of pole line hardware used to connect and support the LED light of the light pole.

The street light arm has many names, these include street light pole, mounting street light bracket arm, street light mounting arm, street light arm bracket, street light pole arm, light pole arm bracket, street light pole brackets, light mounting arm, and others.

What is the function of street light arms?

The primary purpose of using a street light arm is to expand the diameter of the light radiating from a street light pole, so there is more lighting around. It is of great benefit as it helps people see clearly in areas where there is a high chance of animal crossing, pedestrian crossings, and others.

Speed breakers and stop signs often go unnoticed when they are not highlighted at night. At night, street light arms play an essential role in making these things and signs prominent.

What are the main parts of a street light arm?

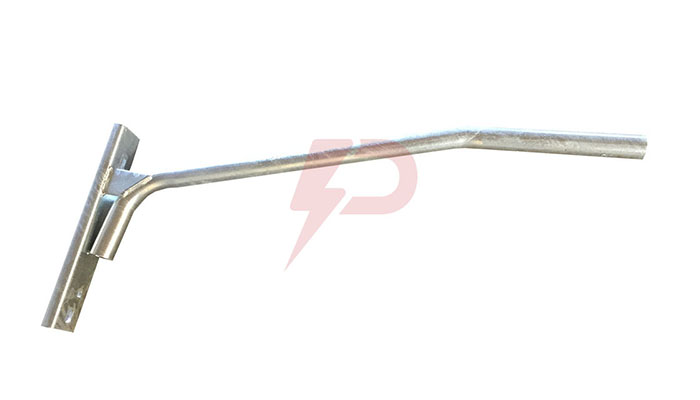

The main parts of a street light arm are the following two parts:

- Flat steel

- Steel tube

As the name indicates, the flat steel serves as a flat base over which the steel tube is affixed. There are two addresses small flat steels that are added on to the two materials already joined so that the base becomes stronger and sturdier than it was before. The metal arc welded street light arm is then made into a stronger structure that can support the underlying components better.

How to use a street light arm?

A certain length of the parallel tube is the dimension of the street light arm at one end. Here, the LED part of the mounting arm bracket is fixed.

The next part of the light mounting arm is the bracket base. It is the closed end part with holes through which connecting cables pass through.

Types of street light arms

Let’s now talk about the types of the street light pole and the types of street light arms as these are the deciding factors depending on which the demand of the street light arm is met.

Street light pole of wood: the street light arm for wood is made in compliance with the set rules of the manufacturing company and is made sure to rightly fix with the wooden pole.

Street light pole of steel: the street light arm for steel pole is a little different from the street light arm for wood pole in the terms that the joining sides are integrated differently, moreover, there are narrower circles made for passing cable.

Steel street light poles are more common than wood ones as the latter ones are not much popular in harsh weather conditions. You will generally find street light poles of steel in most of the urban and residential areas. The street light poles made of wood are more common for drier places with a significantly lower chance of humid weather conditions like rainfall.

Why street light arm is important?

We have described in the above sections that street light arm is important for enhancing the intensity and spread of light. However, this is not the only cause of why a street light arm is important. Most of the poles are present at the height where it is very difficult for a downward spread of the light.

The curvature in the street light arm resolves this problem and makes sure the even spread of light. Moreover, the LED is rendered safer as it is secured in a flat steel and steel tube structure. It improves the overall life of the street light pole to a significant extent.

How to manufacture a street light arm?

The street light arm has a parallel tube that comes with a total length around 150 to 400 mm. It is used for assembling the light mounting pole to the LED. The other end is affixed on the street light pole and is called the bracket base.

The light pole bracket is mainly composed of flat steel and steel tube, both of which are new and do not come in any recycled form. The steel tube is welded on the base made of flat steel and has a thickness of around 2 to 4 mm. Additionally, two steel flats are fixed between the two structures for giving stability to the two structures joined: the steel tube and the flat steel base.

After the final assemblage takes place through welding, the next step is to clean the street light arm by the process of sandblasting. The cleaned street light arm is then dipped into a hot galvanizing solution according to set standards to stay protected from corrosion.

A second time selection is made to ensure the quality of the product. After passing the SGS inspection test, the street light arm is packaged and delivered to the intended customers.

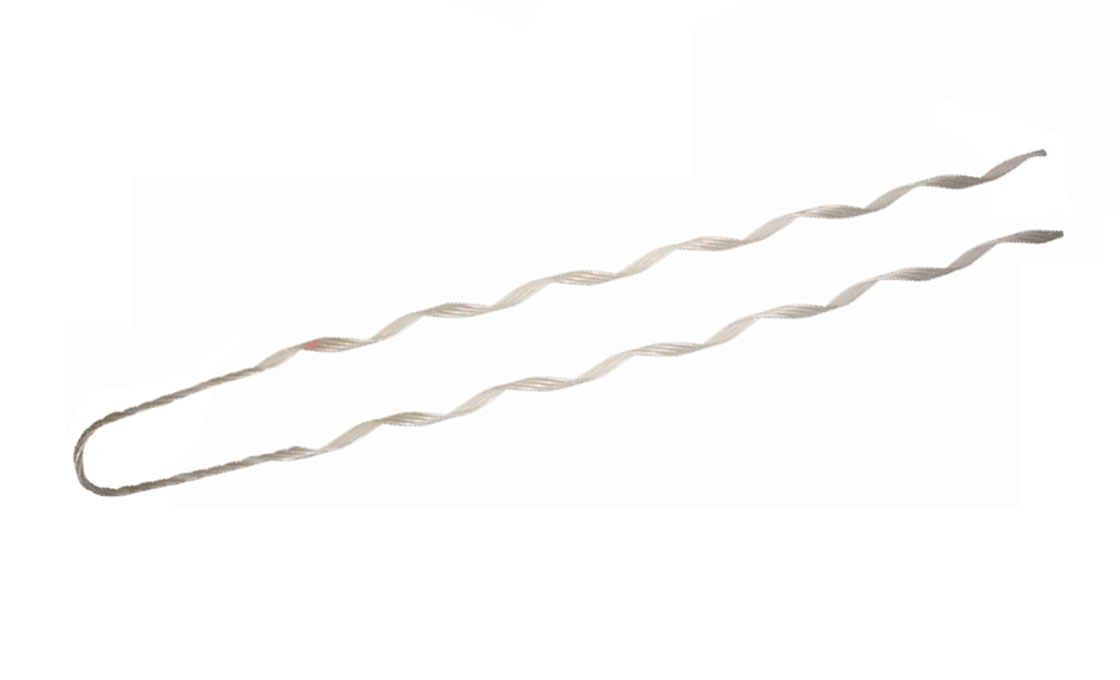

What is the process of galvanizing the street light arm?

The manufacturers make sure that after the welding process is over, the whole structure goes under cleaning, so there will be no edge appearing on the holes or any other part. Otherwise, it can damage the supporting equipment, such as the cables passing through the light mounting pole arm., By the process of sandblasting, any slag and platter are removed carefully with the right cleaning techniques.

The street light arm or street light bracket arm is then subjected to zinc galvanizing. The zinc layer protects the street light arm from the corrosive effects of the harsh environment.

In the process of galvanization, zinc is added into the liquid solution. When the street light arm is dipped into the solution, an electric current is also passed through the solution. Street light arm also can be hot-dip galvanized. It makes the zinc a coating on the street light arm bracket. This is how the street light arm becomes galvanized.

As the street light arm is galvanized, it is coated with the zinc layer. harsh effects of the environment. This adds to the quality of the final product. The SGS inspection makes sure to improve the quality control check of the galvanized street light arm bracket.

Street light arm bracket specifications and features

We as manufacturers pay attention to everything that matters, so you can rely on the company as we provide the best services In terms of the manufacture, packaging, and supply of the street light arm bracket.

The specification of the arm of the product are as under:

- Made of a single piece of hollow, tubular formed mild steel without circumferential welds, or joints. It is welded smoothly into the desired shape with no kinking or any deformation in the whole structure.

- ISO 1461 is complied with while galvanizing the structure to make sure the quality of the product remains good.

The specifications of the bracket of the product are as under:

- Made of a single piece of mild steel with no circumferential welds or the use of joints

- Front section to have a drilled hole that will accommodate a bolt of 3/8th of the total diameter

- The length is required to be of 3/4th of the total diameter

Testing of the street light arm bracket

The product when made is not directly packaged and supplied to the market. It is undergone a series of testing in compliance with the standard testing procedures and rules. This is done to make sure the product lives up to the set standards and is credible to use for a long time. The main inspections included in the final testing of the product include some of the following testing procedures:

- Visual inspection: in visual inspection, the street light arm is heavily inspected of any faults in the structure and dimensions. Also, it is checked whether the type of street light arm is suitable for its structure made or not. This all comes in the category of the visual inspection of the product.

- Verification of dimensions: the team of manufacturers has agreed to comply with the standard rules set by the authority to make sure the final street light arm product is meeting the right dimensions. For this reason, the street light arm is made to be checked thoroughly in terms of its dimensions. If there is any glitch in the dimension, the product is immediately stopped from getting packaged or delivered. The batch is reinspected and made to comply with the standard rules.

- Galvanizing: the final product is then subjected to galvanizing. We have described the process of galvanizing in the above section.

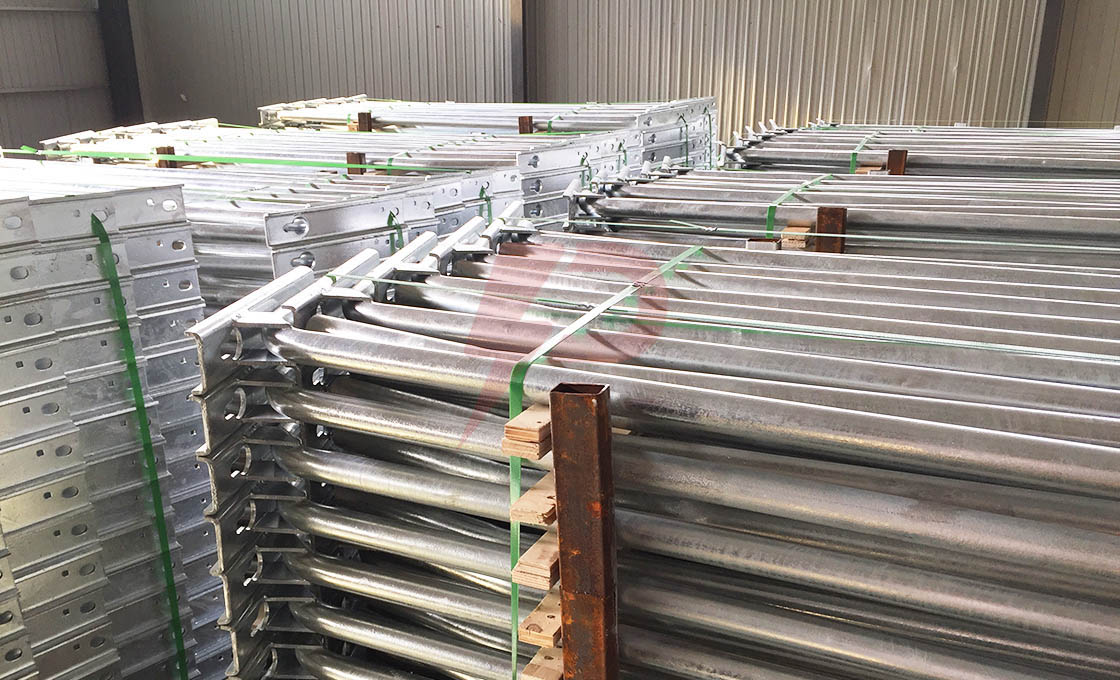

Packaging and delivery of street light arm

A street light arm is packaged in suitable material and then affixed to the base with the help of straps. These straps are made of either plastic or metal and help the structure stay affixed on the ground or the base. This saves the product from undergoing any damage and therefore the integrity of the product is kept saved.

After the street light arm, the street light arm for steel pole, or the street light arm for wood pole is packaged, it is delivered. The manufacturers also offer services where they supply the street light pole accessories such as the street light pole clamp or the street light mast arm.

Final word

Final word

So, we see that the street light arm is a popular yet important component of the street light pole that is used to enhance the light coming from the LED. Many residential and commercial areas have an abundance of street light poles that have street light arms on them.

Our manufacturers make sure the quality of the street light pole mounting bracket is made the top class so there is a minimum need to change the bracket. This ensures the longevity of the LED as well. With a quality control on all procedures, this product is made in the best characteristics.

Frequently asked questions? (FAQs)

What is a street light arm?

Street light arms are widely used outside the streets present on street light poles, they are one type of pole line hardware used to connect and support the LED light of the light pole.

What is the function of street light arms?

The street light arm is used to enhance the intensity and spread of light.

How to install a street light arm?

A certain length of the parallel tube is the dimension of the street light arm at one end. Here, the LED part of the mounting arm bracket is fixed.

The next part of the light mounting arm is the bracket base. It is the closed-end part with holes through which connecting cables pass through.

5 tips when choosing a street light arm manufacturer.

- Price is extremely important, but it shouldn't be your sole criterion for choosing a partner.

- Know the quality assurance steps they take, and Check the quality of the products in stock.

- Good customer service is the premise of offering fast and convenient support.

- Make sure the production capacity of the manufacturer is enough and they can deliver on time.

- Schedule a factory visit for field inspection if you have the budget.