Grounding Ball Stud

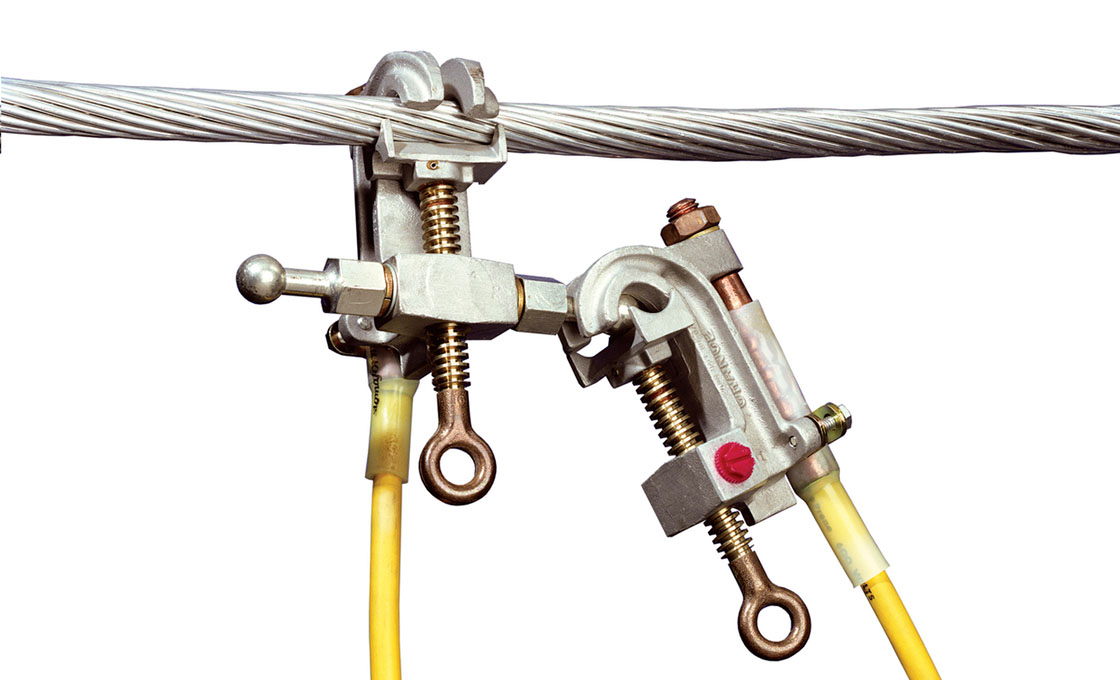

Grounding ball studs are an innovation that some call the unsung heroes of electrical systems. They’re a true testament to engineering expertise and are primarily used to allow for a consistent pathway of electrical currents to be able to dissipate into the ground safely.

In terms of performance and safety, the grounding ball stud is a crucial component in electrical systems. It’s used in industrial settings, power distribution units, and electrical equipment. Its application spans wide sectors of industry, especially where electrical grounding is paramount to the safety and performance of systems.

Basically, the grounding ball stud is used to establish a low-resistance path for electrical currents. This will allow those currents to dissipate into the ground, preventing static electricity buildup and reducing the risk of electrical shocks or damage to sensitive equipment.

Once the ball stud is installed, it creates a seamless connection between the electrical system and the ground. The mechanism is intended to safeguard not only equipment but personnel and maintain a stable electrical environment.

There are a few accessories used with the grounding ball stud. Things like grounding cables, connectors, and grounding bars all help with the functionality of this part. Combined, they create a comprehensive grounding system.

Features:

- Robust construction

- Low-resistance design

- Versatile applications

- Easy integration into electrical systems

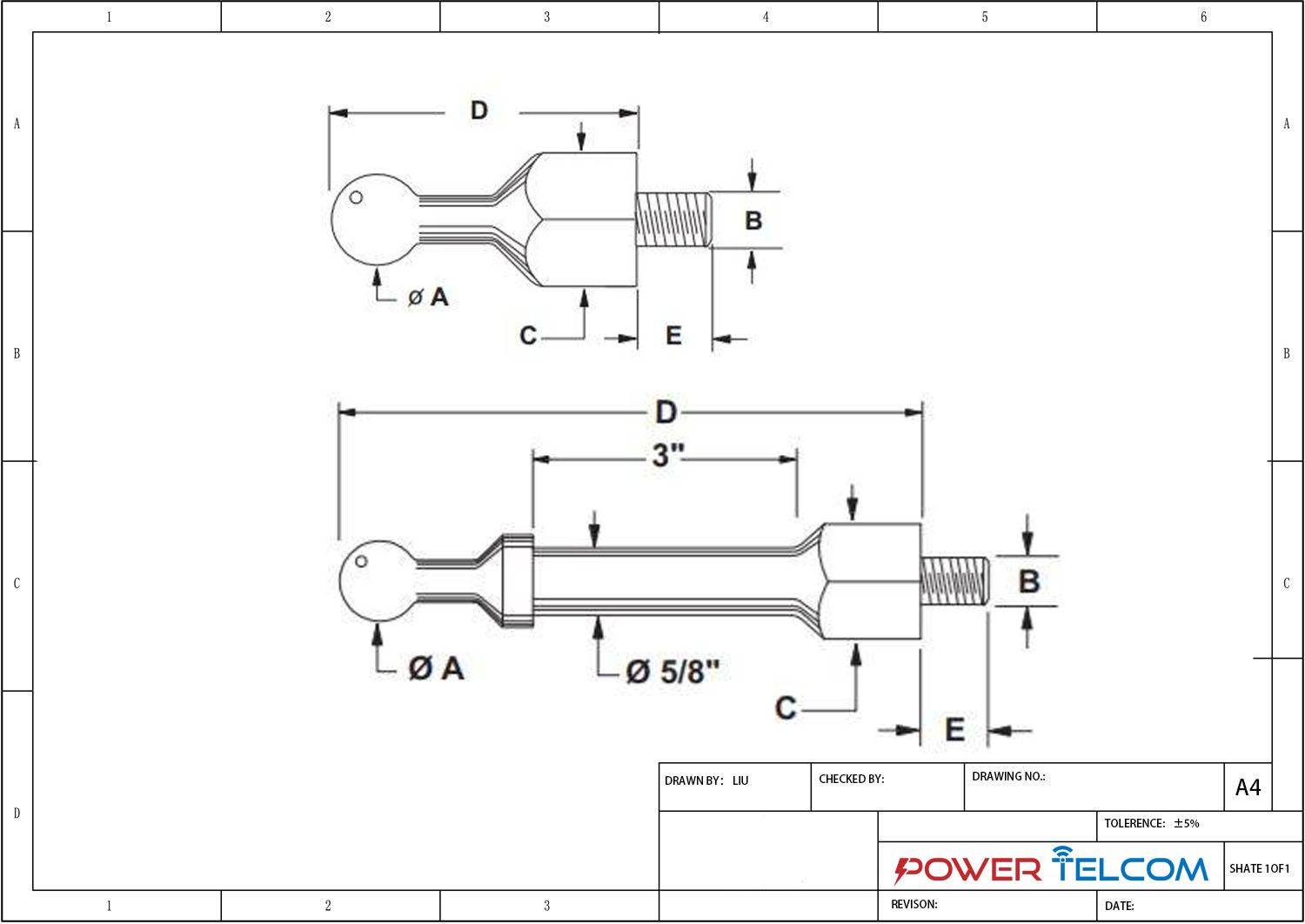

Grounding Ball Stud Drawing

| Catalog Number | ASTM Grade | A | B | C (in) | D (in) | E | Weight (lbs) |

| 03-M-006 | 5H | 20mm | 1/2″-13 | 7/8 | 2-5/16 | No Screw | 0.2 |

| 03-M-006-0.5 | 5H | 20mm | 1/2″-13 | 7/8 | 2-5/16 | 1/2 | 0.3 |

| 03-M-006-1 | 5H | 20mm | 1/2″-13 | 7/8 | 2-5/16 | 1 | 0.4 |

| 03-M-026 | 5H | 20mm | 1/2″-13 | 7/8 | 4 | No Screw | 0.6 |

| 03-M-026-0.5 | 5H | 20mm | 1/2″-13 | 7/8 | 4 | 1/2 | 0.7 |

| 03-M-026-1 | 5H | 20mm | 1/2″-13 | 7/8 | 4 | 1 | 0.7 |

| 03-M-027 | 5H | 20mm | 5/8″-11 | 1 | 4 | No Screw | 0.8 |

| 03-M-027-0.5 | 5H | 20mm | 5/8″-11 | 1 | 4 | 1/2 | 0.9 |

| 03-M-027-1 | 5H | 20mm | 5/8″-11 | 1 | 4 | 1 | 0.9 |

| HC-30012 | 5H | 30mm | 5/8″-11 | 1-1/2 | 4-3/8 | No Screw | 1.8 |

| HC-30012-0.5 | 5H | 30mm | 5/8″-11 | 1-1/2 | 4-3/8 | 1/2 | 1.9 |

| HC-30012-1 | 5H | 30mm | 5/8″-11 | 1-1/2 | 4-3/8 | 1 | 1.9 |

| HC-30015 | 5H | 20mm | 1/2″-13 | 7/8 | 6 | No Screw | 0.8 |

| HC-30015-0.5 | 5H | 20mm | 1/2″-13 | 7/8 | 6 | 1/2 | 0.9 |

| HC-30015-1 | 5H | 20mm | 1/2″-13 | 7/8 | 6 | 1 | 0.9 |

| HC-30028 | 5H | 20mm | 5/8″-11 | 1 | 2-5/8 | No Screw | 0.7 |

| HC-30028-0.5 | 5H | 20mm | 5/8″-11 | 1 | 2-5/8 | 1/2 | 0.8 |

| HC-30028-1 | 5H | 20mm | 5/8″-11 | 1 | 2-5/8 | 1 | 0.8 |

| HC-30029 | 5H | 25mm | 1/2″-13 | 1 | 3 | No Screw | 0.5 |

| HC-30029-0.5 | 5H | 25mm | 1/2″-13 | 1 | 3 | 1/2 | 0.6 |

| HC-30029-1 | 5H | 25mm | 1/2″-13 | 1 | 3 | 1 | 0.6 |

| HC-30036 | 5H | 25mm | 1/2″-13 | 1 | 6-1/4 | No Screw | 1.1 |

| HC-30036-0.5 | 5H | 25mm | 1/2″-13 | 1 | 6-1/4 | 1/2 | 1.2 |

| HC-30036-1 | 5H | 25mm | 1/2″-13 | 1 | 6-1/4 | 1 | 1.2 |

| HC-30037 | 5H | 25mm | 5/8″-11 | 1 | 3 | No Screw | 0.4 |

| HC-30037-0.5 | 5H | 25mm | 5/8″-11 | 1 | 3 | 1/2 | 0.5 |

| HC-30037-1 | 5H | 25mm | 5/8″-11 | 1 | 3 | 1 | 0.5 |

Grounding Ball Stud – A Simple Guide

Grounding ball studs are a tool that’s used in electrical work. They’re designed to help build a pathway for electrical currents to ground themselves into the soil safely.

Why Grounding Ball Studs?

These small but essential components are usually created with corrosion-resistant high-grade materials such as copper alloys and steel. Using these materials allows them to ensure durability and resilience in a wide range of conditions. On top of that, it can provide a way for electrical curves to dissipate into the ground safely.

The contours of the state itself allow for easy installation and securing of grounding connections. This, in turn, minimizes downtime and offers efficient integration into systems. The units are compatible with a wide range of grounding systems, and this makes them versatile in a plethora of industries.

Types of Ground Ball Studs

There may be variations that are present on the market, but most grounding ball studs come in one type. This is a universally compatible version that works with a wide range of systems and environments. The versatility of this makes it an invaluable tool in outdoor telecommunications and electrical structures.

How It Works

The materials used – stainless steel and copper alloys – are important because they help with electrical grounding, decreasing the need for consistent maintenance. Along with the reduced maintenance needs, it also optimizes the downtime and associated costs of any maintenance.

Testing of these products ensures reliability under extreme weather conditions, interference from electromagnetic occurrences, and even seismic events. This rigorous testing guarantees high performance no matter what.

How to use a Ground Ball Stud?

These tools are indispensable across a diverse range of industries because they serve as an essential link in electrical systems. They are applied widely to industrial settings, power distribution units, and electronic equipment.

This ensures stable electronic environments by facilitating a safe dissipation of currents. Their versatility allows them to be essential parts of sectors reliant on a comprehensive electrical infrastructure.

Ground Ball Stud Parts

- Stud Body: Main body, threaded for attachment

- Ball Stud: Spherical component allowing rotation

- Ball Socket: Housing for the ball stud

- Bearings: Reduce friction for smooth articulation

- Boot or Seal: Protects against debris and moisture

- Circlip: Secures the ball stud in the socket

- Grease Fitting: Allows for lubrication

- Jam Nut: Secures the ball stud in place

Factors to Consider When Choosing

When looking for the right grounding ball stud, there are several things you must consider. First, you need to consider the compatibility of the various systems, adaptability to environments, and the ability to hold up to extreme weather conditions.

You may also want to consider the esthetic which might include polished finish and attention to detail. These are all things that could help ensure better performance and easier installation.