Eye Nut

This eye nut is specifically designed for dead ending and for attaching the pole head guys into the cross arm bolts. The eye nut can also be used for back guying on a power line.

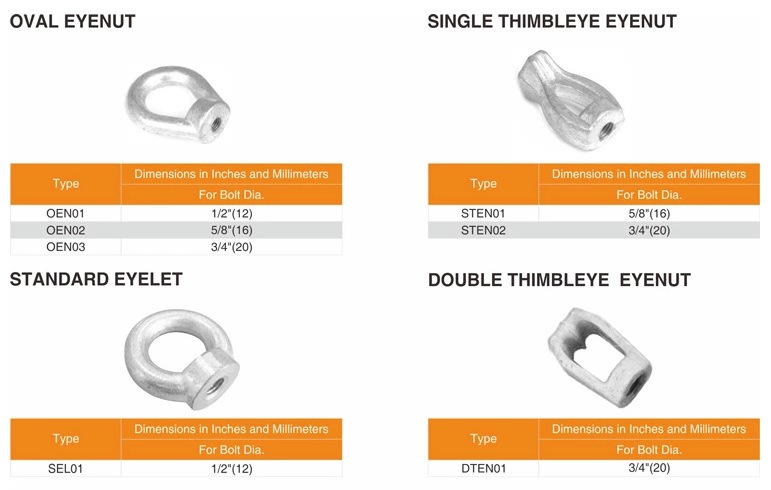

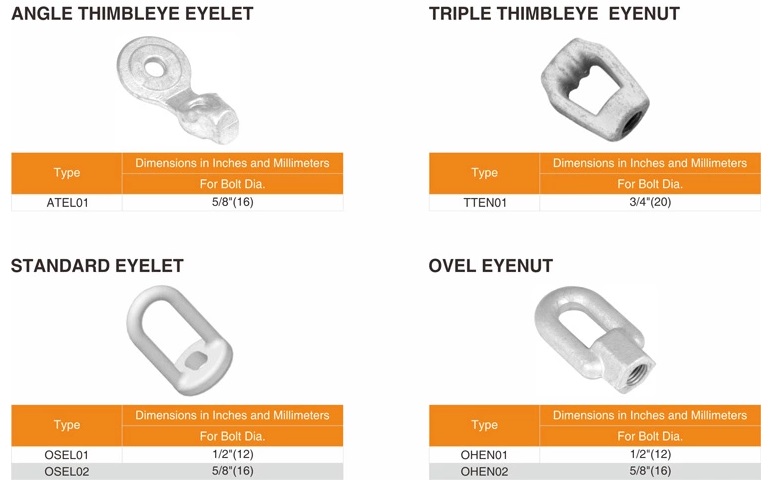

Eye nut for power line comes in different varieties. These are the thimble eye nut, angle thimble eye nut, and the oval eye nut. All of them are applicable to any power line.

The eye nut is made of quality carbon steel material. The massive strength of this material ensures that the device remains durable and will serve you for long.

The eye nut is further polished to be protected from corrosion and physical abrasion when exposed to water and chemicals It is also resistant to rust and other similar negative elements.

Our eye nut for electric pole lines comes with different specifications. For instance, the thimble eye nut can either have a twin eye or a thimble eye.

The oval eye nut, on the other hand, is threaded with 1/2” or 5/8” bolts which are passed vertically to connect with dead end clamp. The thimble eye nut has the same size of threads as the bolts which connect insulators to the dead end wire.

In terms of design, the eyes nut have a simple but elegant design. This simplicity allows them to be installed and used without any complications. The eye nut features internal threading and a looped head.

If you want to buy an eye nut for your electric power line project, simply contact a reliable eye nut manufacturer in China. You will get more information including the price of eye nuts.

Eye Nuts Complete Buying Guide

When it comes to electrical and telecommunication projects, choosing the right tool for the job can make a major difference between the success and failure of the project. This is vital because projects that are connected to these two industries are quite sensitive especially on matters of safety.

Eye nuts are such tools. With the right eye nuts, your wires and cables will be properly connected and secured.

Are you planning to buy quality eye nuts in China? Be glad that you are in the right place. In this article, I am going to cover all the essential details of eye nuts.

- 1. What is an eye nut?

- 2. What are the materials for eye nuts?

- 3. Applications of eye nuts

- 4. How are eye nuts manufactured?

- 5. Classification of eye nuts

- – Load rated and unrated eye nuts

- – Fully threaded nuts vs partially threaded eye nuts

- 6. Features of eye nuts

- – The maximum load capacity of the eye nuts

- – Eye nuts Thread Sizes

- – Eye nuts specifications that you should know

- 7. Eye nuts installation and maintenance

- 8. Precautions for using eye nuts

- 9. Choosing eye nuts manufacturer in China

What is an Eye Nut?

Simply defined, eye nuts are fasteners that have lopped heads. They are designed to secure wires, cables, and even ropes through hooks. The shape of the eye nut head can be round or oval-shaped depending on the area of application.

Simply defined, eye nuts are fasteners that have lopped heads. They are designed to secure wires, cables, and even ropes through hooks. The shape of the eye nut head can be round or oval-shaped depending on the area of application.

Eye nuts are usually used for vertical lifting. It is not advisable to use them for the angular lifting as this can affect their reliability and effectiveness.

However, some eye nuts which are not load-rated are used for pinning down against the cables or wires. Such eye nuts are not ideal for lifting applications.

What are the Materials for Eye Nuts?

Eye nuts are made of different materials. Each material of the eye nut has a unique set of properties that will eventually affect the performance of the eye nuts.

The most common materials for eye bolts are aluminium, stainless steel, alloy steel, and galvanized steel. The properties of these metals are the reasons why they are the most preferred materials for making s eye nuts.

First, the stainless steel is resistant to rust. It contains elements such as nickel, chromium, and molybdenum which protect the iron in the steel alloy from rusting.

This means that the eye nuts will be used anywhere regardless of the external factors which can contribute to rust. You can even use the eye nuts in the marine environment and their physical property won’t be affected by rust or any other external factors.

Eye nuts that are made of alloy steel tend to be suitable for use in cold weather. Since the lifting process usually takes place when the temperatures are low, the eye nut will still perform its role effectively as required. Its structure won’t be affected by extreme temperature changes.

Both stainless steel and alloys steel are capable of retaining their metallurgical properties. In addition to being rust-proof, they still retain their tensile strength.

Galvanized steel is another common material that is used for making eye bolts. This material is simply steel that has been dipped in molten zinc. The zinc coating protects the eye bolt from corrosion hence making it suitable for outdoor applications.

All in all, it is clear that the material for eye nuts should be capable of withstanding various outdoor conditions. It should also withstand the physical force or load that is subjected to when in use.

Although steel is the most preferred material for eye nuts, it is not rare to find brass eye nut. It may not be as strong as steel but can execute its role perfectly.

Applications of Eye Nuts- Eye Nuts Uses

Eye nuts have a wide range of applications. They can be used for both domestic and industrial purposes. Here is a list of the most common applications of eye nuts.

-In the industrial setting, these fasteners are used for lifting and tensioning the cables. A perfect example includes applications such as power lines and telecommunication cables.

-At home, they are used to providing platforms for hanging things on the wall.

-Eye nuts can also be customized to work in the machinery and equipment that you want.

The quality construction of the eye nuts is just one of the reasons behind their widespread applications. Their performance cannot be easily hampered by external factors such as weather conditions.

Also, the fact that these eye nuts come in different designs makes them suitable to be used in different applications. You only need to inform the lifting bolt manufacturer where you intend to use the nuts and they will customize it.

How are Eye Nuts Made? Fabrication Process

There are two critical processes that are used for giving eye nuts their final shapes. These are forging and bending. From these two processes, you will be able to get a solid piece of rod to take the shape of an eye nut.

Forged eye nuts are usually hammered or even pressed until their grain structures change. The end result is a strong and durable eye nut that can withstand external forces.

Forged eye nuts are an ideal choice for heavy-lifting tasks. They have a high tensile strength which to withstand such forces. Also, it is possible to get large eye nuts from this process.

On the other hand, bent eye nuts are made when a piece of steel rod is manually bent to form the shape of an eye.

Bent eye nuts are only suitable for lighter applications. They are not capable of lifting heavy loads. They are also not suitable for angular lifting.

Classification of eye nuts

Load Rated and Unrated Eye Nuts

Load Rated and Unrated Eye Nuts

Although there are many different ways of classifying eye nuts, the most basic method is by load rating. This criterion of classification is based on the fact that eye nuts are made of steel.

Load-rated eye nuts are specifically designed for vertical lifting. It is not recommended to use these eye nuts for angular lifting.

On the other hand, eye nuts that are not rated are not suitable for lifting uses. Instead, they must be used together with the guiding wires or with tie-downs.

Fully Threaded Nuts vs Partially Threaded Eye Nuts

Another way of categorizing different types of eye nuts is based on their threads. An eye nut for sale can either be fully-threaded or partially threaded. what is the difference between these two types of eye nuts?

Fully threaded nuts mean that the entire eye of the nut is threaded from the top to the bottom Partially threaded means that some sections of the eye are not threaded as expected.

Given the nature of the threads, it is imperative to note that the two types of eye nuts are used for different purposes. With a fully threaded nut, the tension that exerted on it spreads to the whole structure. It is not just concentrated on point. This means that these eye nuts are capable of withstanding more tension force than partially threaded nuts.

Another advantage of the fully threaded eye nuts is they rarely shear. They also rarely loosen too much when subjected to external forces that can cause vibrations.

On the other hand, partially threaded eye nuts are used where the factors of shear resistance and are prioritized. The fact that they don’t have many threads means that nut will have excellent shear properties.

In case you are not sure of which eye nut to pick, consider consulting eye nut experts or even directly contact eye nuts manufacturers for more information.

Features of eye nuts

The Maximum Load Capacity of the Eye Nuts

Each eye nut comes has a maximum load capacity. This is the maximum weight of a load that the eye nut can handle.

You should never exceed the load capacity eye nut as this can cause it to break or even malfunction.

The load capacity of nut eyes tends to vary with the type of material used. Some materials tend to have a higher load capacity than others.

Eye Nut Thread Sizes

The thread sizes of eye nuts are measured in inches and millimeters. The most common thread sizes include; 1/4, 3/8, 5/16, 7/12, 1/2, 7/8, 3/4, 1, 11/8, 11/4, 13/4, 2, 21/4, 21/2.

These thread sizes are usually designated as #16, #18, #20, #24. The metrics for the eye nuts include M16, M18, M20, M24, M26, M30, M32, M36, M38, M40, M42, M54 M48, and M56.

In these metrics, the M is used to denote the number of millimeters in the eye nut diameter.

When buying eye nuts in China, ensure that you give the thread sizes some special attention. Incorrect size of thread my not be suitable for your application.

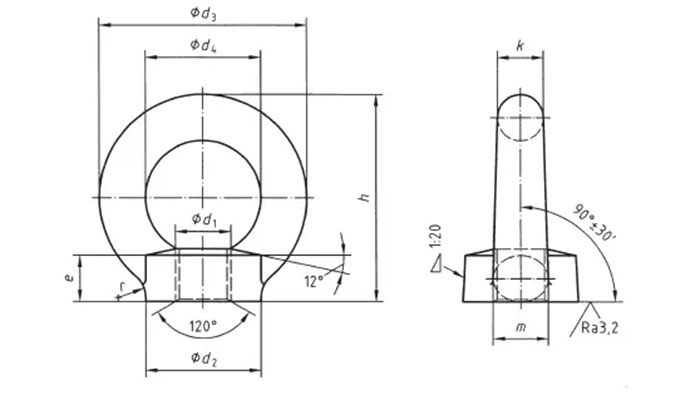

Eye Nut Specifications that you Should Know

When buying eye nuts for sale, there are several specifications that you should look at. Here are some of them.

- Bell diameter: A bell is a part of an eye nut that contains the tap. These sections come in different diameters. When buying this nut you may specify the diameter to be at least or not exceed a particular value. It all depends on your application area.

- Threaded length: This dimension refers to the length of the threaded section of the tap. Again the values can be minimum or maximum according to your requirements.

- Inside diameter/width: This is basically the bail size of the eye nut. It is applicable in both round nuts and oval nuts.

- Eye section diameter: This is the thickness of the eye which is sometimes known as the bail of an eye.

- Eye nut weight: This is used for referring to the overall weight of an eye nut. In most cases, the weight of an eye nut is determined by the material that has been used to construct it.

Eye Nut Installation and Maintenance

In the same way that you were careful in choosing eye nuts, you should extend the same precaution when it comes to installation and maintenance.

Installing the eye nuts properly will ensure that they serve their functions effectively.

Here are some of the recommended guidelines for installing and maintaining eye nuts:

-Always clean the eye bolt threads before using the nuts. This will ensure that the eye nut is properly attached to the fastener.

-Ensure that the loads are always aligned to the plane of the eye rather than to the angle. You can use a steel washer to attain proper alignment.

-Inspect the seating of the eye nut after applying the lift. This is to ensure that the eye nut is stable. If it is unstable, reseat and install it again until it attains the desired stability.

Precautions for Using Eye Nuts

Here are some of the precautionary measures that you should take when using eye nuts;

-Do not force a sling to pass through the eye.

-Never overtighten an eye nut

-Don’t force hooks and other fittings through the eye nuts. The connection should be done freely.

-Do not exceed the rated capacity of the eye nut.

-You should never use an eye nut that has signs of wear

-You should never shock-hold an eye nut. Instead, do the lifting in a gentle manner

-Do not try to change the physical properties of an eye nut through grinding or any other methods.

-Do not paint the eye nuts or even using any coating on them. Most paints tend to make it difficult for one to inspect the state of the eye nut and detect any problem.

Choosing Eye Nut Manufacturer in China

Looking for a quality and affordable eye nuts for your project? The surest way is to buy from affordable eye nut manufacturers and suppliers in China. This way, you will get a true value for your money.

At Powertelecom, we design and manufacture quality eye nuts in China. Our eye nuts are perfectly suited for powerlines and telecommunication systems.

In addition to the standard sizes of eye nuts, we can also get you customized eye nuts that will fit into your project. Through our platform, you can even buy eye nuts online. Contact us and place your order regardless of where you are.

Load Rated and Unrated Eye Nuts

Load Rated and Unrated Eye Nuts