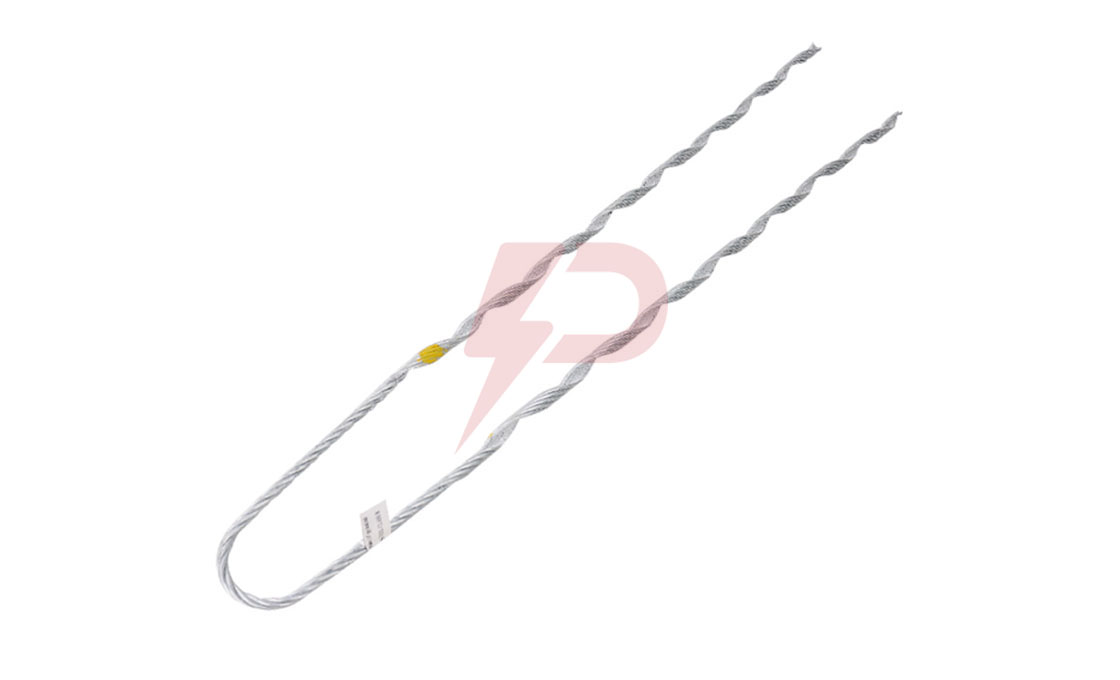

Armor Rod

The armor rod, also known as the spiral vibration damper, is made of a solid PVC rod and is designed in a spiral form so it suits the diameter of the cable which will be used with it. The vibration damper has two sections – the gripping section and a dampening section.

A vibration damper is a visco-elastic material having the characteristics of both solid and liquid state. This substance assists in absorbance of some energy from vibration which is then dissipated as heat energy. Moreover, some of the energy is stored when the pressure gets turned off.

If any product can not be designed to receive all resonant frequencies, vibration dampers are the tools that absorb that extra vibrational energy which lowers the frequency and alleviates wear and tear on an electronic part or an engine while even minimizing the risk of a potential break down.

To control the risks associated with vibrations, our good quality vibration dampers are helpful regarding the safety of the machine producing those vibrations. Our flexible and light weight vibration dampers are specifically engineered to cater to all needs.

The armor rods are adjusted according to the frequency of the noise and thus helps in alleviating the unnecessary vibrational sounds. Our vibration dampers follow the standards set by the regulatory bodies so that there is no room for error. Quality assurance and control on the cost of the dampers are some important factors kept in mind while creating the product. The long-lasting material is durable and is meant to perform at its best for a long period of time.

The waterproof and resistant to wear dampers are specifically designed to go well with almost all kinds of machines when needed. You will not have to worry about the noisy vibrations in your machines anymore with this damper.

| Catalog No. | Cable Range(inches) | Unit Wt.(lbs) | Units per carton | Length(inches) | Rod Dia.(inches) | Rods per set | Color code | |

| Min. | Max. | |||||||

| LRAR-10106 | 0.194 | 0.207 | 0.35 | 100 | 40 | 0.121 | 7 | Blue |

| LRAR-10306 | 0.45 | 100 | 52 | |||||

| LRAR-10107 | 0.208 | 0.219 | 0.35 | 100 | 40 | 0.121 | 7 | Black |

| LRAR-10307 | 0.45 | 100 | 52 | |||||

| LRAR-10108 | 0.220 | 0.228 | 0.40 | 100 | 40 | 0.121 | 8 | White |

| LRAR-10308 | 0.51 | 100 | 52 | |||||

| LRAR-10109 | 0.259 | 0.259 | 0.40 | 100 | 40 | 0.121 | 8 | Brown |

| LRAR-10309 | 0.51 | 100 | 52 | |||||

| LRAR-10110 | 0.260 | 0.273 | 0.50 | 50 | 40 | 0.146 | 7 | Orange |

| LRAR-10310 | 0.61 | 50 | 52 | |||||

How to make hot-dip galvanization perfect?

For the different types of pole line hardware, there are different ways to do the hot-dip galvanization.

For the electrical cross arm, alley arm, the manufacturer does the hot-dip galvanization at a big bow, the liquid temperature was controlled very well. And the consist element was settled according to a certain percent.

For the casting part like socket clevis and pole top bracket, there is a different element consist to do the hot-dip galvanization.

What is the hot-dip galvanization test standard?

There are a few kinds of hot-dip galvanization testing standard for the overhead line fitting.

For the Asia market, like Malaysia and Indonesia, they test the hot-dip galvanization according to ISO1461.

For South America, they test the hot-dip galvanization according to ASTM123.

Who will charge if making a new design?

The manufacturer usually charges the tooling, if you don’t accept our present power fitting type.

The manufacturer will make new tooling based on your design, and the new tooling belongs to you. The manufacturer just helps you to take care of the tooling in our factory.

If you have paid for it, the manufacturer can also refund you the tooling cost if you ordered a certain quantity.

Can we get a sample before placing an order?

Yes, of course. It’s a necessary step to confirm the sample before mass production.

If the type of pole line hardware you required is in stock, the customer will only burden the express cost and have the sample for free.

If you need to make new samples according to your drawing, you should charge the sample cost.

What’s the payment item?

Only T/T and L/C are acceptable, OA is not.

What is the delivery time for the power fitting?

If the pole line hardware you required is in stock, the goods will be shipped immediately after you pay.

If there is no stock for your required, 20 days are needed to make 1*20 containers and confirm further whether it is needed to make new tooling for it.