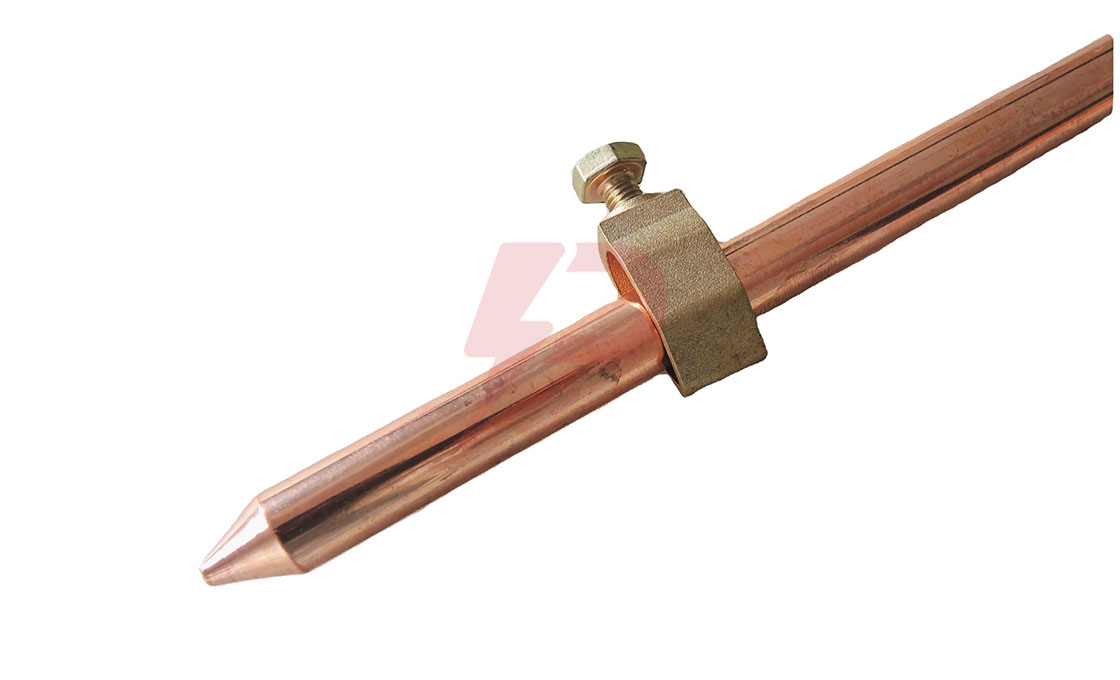

Ground Rod

A ground rod is the most common type of electrode used for the grounding system. It can be made of several materials: copper-bonded steel, Stainless Steel, Galvanized Steel, and Solid Copper. It provides a direct connection to the ground. In doing so, they dissipate the electric current to the ground. The ground rod significantly improves the overall performance of the grounding system.

Ground rods are applicable in all types of electrical installations, as long as there is you are planning to have an effective grounding system, both at home and in commercial installations.

Ground rods are defined by specific levels of electric resistance. The resistance of the ground rod should always be higher than that of the grounding system.

Even though it exists as a unit, a typical ground rod comprises different components which are steel core, and copper coating. The two are bonded through an electrolytic process to form permanent bonds. The combination is perfect for the maximum current dissipation.

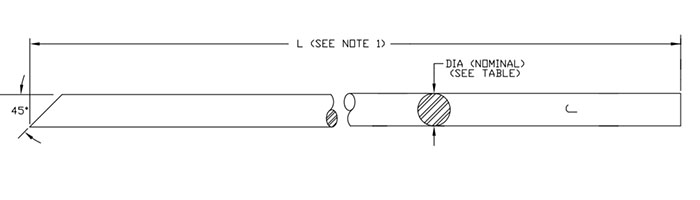

Ground rods come in different nominal lengths and diameters. ½” is the most preferred diameter for the ground rods while the most preferred length for the rods is 10 feet.

Key Features

- Diameters of ½, ¾ and 5/8

- Lengths of 10 foot and 8 foot

- Uniform copper coating all over the rod

- Easy to install

- ANSI and NEMA approved

- Weather-resistant.

| Product No. | Dia. (mm) | Threaded (IN) | Copper thickness (mm) | Length of supply(mm) | ||||

| GR3/8 | 9 | 3/8″ |

0.254 |

1200 |

1500 |

1800 |

2400 |

3000 |

| GR1/2 | 12.5 | 1/2″ | ||||||

| GR5/8 | 14.2 | 5/8“ | ||||||

| GRM16 | 16 | M16 | ||||||

| GR3/4 | 17.2 | 3/4″ | ||||||

| GR1 | 23 | 1″ | ||||||

Ground Rod- The Ultimate Guide

What is a ground rod?

A ground rod is a type of electrode that is installed underground to complete a connection to the ground system. It is sometimes known as the earth electrode.

What is the function of a ground rod?

A ground rod provides a path to dissipate static charge to the earth. This can charge from the electric current or even lightening.

Ground rods are good conductors of electricity. They direct the electrical current from the panel preventing it from going back to the mains.

Application of ground rods

As we have seen, the primary purpose of a ground rod is to dissipate the static charge and the leaking electric current. It is applicable in electrical installations.

Ground rods are installed both at home and business premises. The ground rods help to secure these premises from the dangers that come with the leaked current.

Important features of ground rods

There are certain distinct features that you should look at when buying ground rods. They include;

-Resistant to corrosion: This is one of the primary features that you should consider when buying a ground rod. The material for the rod should be corrosion-resistant, especially when you install it underground. This is important especially when you consider factors such as the pH content of the soil, water, and even salt.

-Ease of installing: While it is easy to assume that the installation simply entails driving the rod into the earth, it is more than that. You have to consider the ease of the process. The rod should not bend whenever you insert it underground.

-Conductivity: The conductivity defines the resistance to the flow of electrical current. After all, this is the primary purpose of the ground electrode. The electrical conductivity differs from one ground electrode to another. Compare them and choose the most suitable one.

Comparing ground rod materials

While in the process of buying ground rods, you are likely to find ones that are made of two materials; copper bonded ground rods and galvanized ground rods. Stainless steel and pure copper are other options that you may encounter.

The choice of the ground rod material may depend on the environmental factors, cost, and durability of the material.

Copper-bonded ground rods are a product of the electro-plating process. Here copper is coated over a stainless steel core. This ends up forming a permanent bond.

Copper bonded ground electrode rods are durable and have high corrosion resistance. They also have the cost advantage as they are easily available. The main test of copper-bonded rods is when they are exposed to extremely saline conditions.

Stainless steel ground rods are also popular. It is important to know that stainless steel is an alloy of iron and other minerals such as chromium. The rod is coated with a layer of oxide for protection.

Ground rods made of stainless steel are unbreakable. This means that they are easy to install as you won’t worry about breaking the rod. Also, the oxide layer shields the rod from corrosion and chemical damage.

Galvanized steel is another material for ground rods. This material is formed by coating steel with a zinc layer. Although it is cheaper than stainless steel, it is not quite strong.

How to install a ground rod

The first step of the installation entails choosing a perfect spot to install. The spot should be at least two meters away from the building. There should be enough space around the installation spot so that you can work with ease.

Drive the rod vertically into the ground. You can then connect the ground rod to the electrical wires and the panel.

It is always advisable to hire an expert to do the ground rod installation.