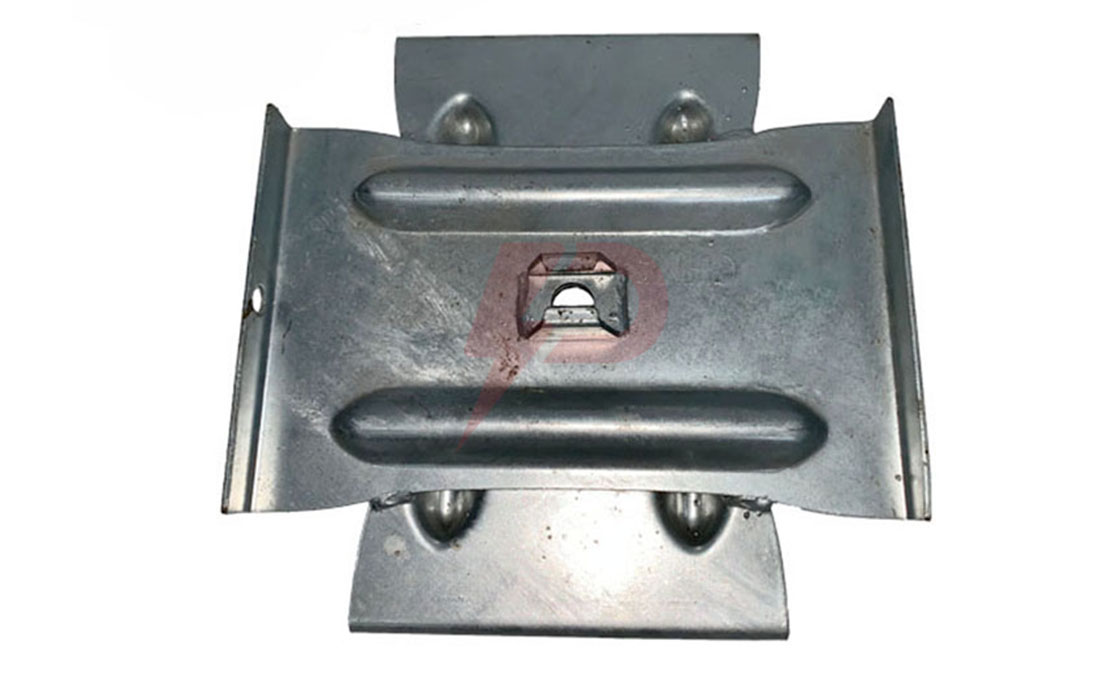

Expanding Bar

To simplify the job of expanding anchor, the improved fiberglass handles expanding and tamping bar are used. The purpose of the curved tamper and the expanding head is to reduce the handle vibration and distribute the weight of the bar.

To distribute the weight of the bar evenly around the anchor rod, the curved head is used, which hooks wrap around the anchor rod.

This tool can also be used efficiently for tamping in soil over the positioned anchor while its base casting is directly attached to the fiberglass handle.

The primary function of expanding bar is to take full advantage of the provided area by expanding because all eight blades wedge into undisturbed earth, so to avoid the wasted space between the edges, this anchor must be installed in comparatively dry and stable soils because the effectiveness of this anchor depends upon the thoroughness of backfill tamping.

FEATURES

- To provide a large offset eye to accommodate three-ton chain hoist hooks, the inexpensive cost-cutter is often used.

- It leaves the anchor eye free with plenty of clearances to attach a formed wire grip.

- Easy to install, can assemble and hook up in minutes.

Frequently asked questions (FAQ)

What is the expanding bar?

It can be defined as that the expanding bar is a broad flat head with a long-handled metal bar used for tamping the ballast under the railroad ties.

What is the function of expanding tamping bar?

The primary function of expanding tamping bar is that it just simplifies the work of developing anchors; it is used to expand the anchor and tamp the dirt in the hole.

How to use expanding bar?

Step by step:

1. Auger the hole with the proper size auger to find the anchor. Oversized holes made with augers typically used for pole holes will cause the anchors to creep and possibly fall.

2. Auger the hole in line with the guy load. Anchors installed vertically and pulled at an angle could result in bending and breakage of the anchor rod.

3. Expand or bust the anchor blades completely, ensuring the cone top is flat against the base plate.

4. Backfill and tamp the hole