U bolt

U bolt is also u bolt clamp, or u clamp, just as the name suggests, this bolt for power and telecommunication line assumes a U-shape. Like other bolts for the electrical overhead line, U-shape is used for connecting dead end and even power line to the pole. It can be used on both the wooden and concrete poles.

Although they are known as U bolt, they are not all the same. Instead, there are some slight variations in the way that they are designed.

These variations of U bolts are; Round U bolt, Square U bolt, and Semi-round U bolt. All these designs or shapes of U bolts can be used on concrete poles.

U bolts for overhead powerline come in different sizes. The smaller ones are mainly used for connecting ball sockets and tension clamps.

In terms of the construction, our U bolts are made of steel rod. This material is known for being strong and durable. It has a high tensile strength that can withstand external forces.

The steel rod is galvanized with a zinc coating that provides surface protection. The coating mainly protects against corrosion.

Would you like to buy U bolts in China? Simply contact us. We are a reputable U bolt manufacturer in China.

| Catalog No. | Dimension | Rated Farilure Load(KN) | Weight(kg) | ||||

| C | D | E | L | M | |||

| U-1240 | 40 | 12 | 45 | 80 | 12 | 35 | 0.39 |

| U-1440 | 40 | 14 | 60 | 90 | 14 | 35 | 0.42 |

| U-1470 | 70 | 14 | 70 | 120 | 14 | 40 | 0.46 |

| U-1670 | 70 | 16 | 70 | 140 | 16 | 50 | 0.80 |

| U-1870 | 70 | 18 | 80 | 105 | 18 | 60 | 0.86 |

| U-1880 | 80 | 18 | 60 | 105 | 18 | 60 | 0.88 |

| U-1890 | 90 | 18 | 60 | 110 | 18 | 60 | 0.90 |

| U-2070 | 70 | 20 | 90 | 115 | 20 | 70 | 1.20 |

| U-2080 | 80 | 20 | 70 | 115 | 20 | 70 | 1.70 |

| U-2090 | 90 | 20 | 90 | 120 | 20 | 70 | 1.28 |

| U-2280 | 80 | 22 | 90 | 130 | 22 | 100 | 1.30 |

| U-2290 | 90 | 22 | 100 | 140 | 22 | 100 | 1.34 |

U-Bolt Complete Buying Guide

U-bolts could seem simple. After all, most of us assume that these are just a bent piece of steel, right? Don’t let their simplicity fool you, U-bolts are often the difference between solid structures and on-site disasters.

It’s easy to overlook these crucial restraints, but we’re here to deliver the must-knows. We’ve ironed out the essentials of those small workhorses.

Read on for a guide to U-bolts and therefore, the simple facts surrounding these compact impact makers. At the end of it all, you will be able to make a smart decision when it comes to buying the best U-bolts in China.

What is U-Bolt?

A U Bolt with Plate

When you break it down, a U-bolt may be a bolt bent into the form of the letter “u.” It’s a curved bolt that features threads on each end. Because the bolt is well curved, it fits nicely around pipes or tubing. Meaning U-bolts can secure piping or tubes to support and work as a restraint.

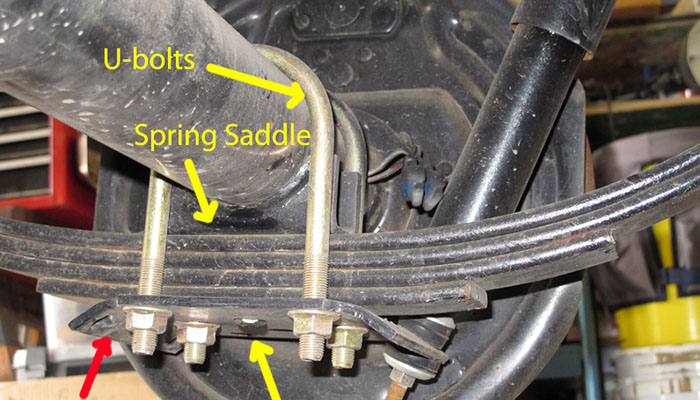

U-bolts have primarily been wont to support pipework, pipes through which fluids and gasses pass. As such, U-bolt dimensions were measured using pipe-work engineering speak. A U-bolt would be described by the dimensions of pipe it had been supporting. U-bolts also are wont to hold ropes together.

U bolts are probably the foremost common type of pipe support, but there are many styles within the category.

Types of U-Bolts

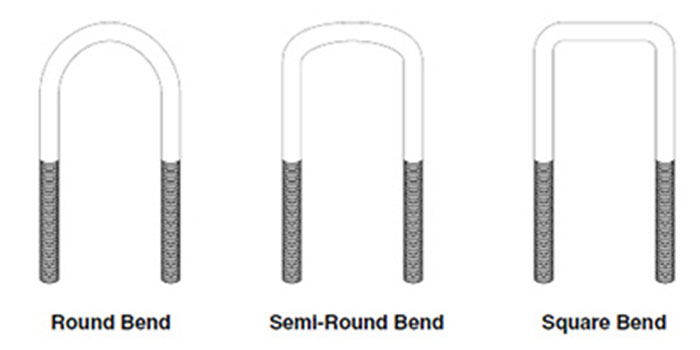

There are three main types of U bolts. These are; Round U-bolts Semi-round U-bolts Square U bolts.

different types of u bolt

As you can tell the difference is based on the U-bolt design and how they are bent. You can also find custom-bent U-bolts that are neither round nor square.

When buying U-bolts, all you need is to talk to the U-bolt manufacturer and specify the type that you want.

1. Square bolts

As the name suggests, these types of U-bolts are bent to resemble the shape of a square. This design allows them to fasten items into box section structures. They are basically used for clamping rectangular and square items.

In most cases, these bolts usually find themselves within the suspension of the metal ductwork and even channels.

Square U-bolts can also be embedded in concrete materials and be used as anchor bolts for heavy equipment and machinery. It is also a common type of U-bolt that is found in the marine application.

2. Round U-Bolts

These U-bolts are mainly used on structures that tend to assume the round shape hence the name. They can be used for attaching round bars, pipes, and even on the steep posts.

Round bolts can also be attached to the concrete poles where they will function as anchor bolts.

3. Semi-round U-bolts

These U-bolts are slightly similar to the round U-bolts in terms of the design and configuration. They are also used on structures that are partially round.

4. Custom U-bolts

This type of U-bolt is neither round nor square. It is specifically customized to suit the specific needs of its application area, such as slant u bolts.

U Bolt Materials

A U-bolt should be strong to perform its work efficiently regardless of the area of application. The strength of any U-bolt for sale is determined by its material.

U-bolts are often made from all types of materials. But they’re usually made from durable metal that’s noncorrosive. Here are some common materials at the guts of U-bolts:

- Plain steel

- Carbon steel

- Stainless steel

- Aluminum

So, which type of U-bolt will fit your application? There are many parameters that you can use to gauge the effectiveness of any U-bolt type.

U-bolt experts or even the manufacturers of U-bolts can guide you on choosing the right type of U-bolt.

Applications of U-Bolts

As a piece of formed faster, U-bolts have a wide range of applications in different industries. Some of the industries that heavily depend on U-bolts include;

-For supporting piping structures

-Wire cable

-In automotive leaf spring

-keeping the antenna section stable and secure

How are the U-bolts used?

To make things clearer, let’s highlight how the u-bolts are used for their respective applications.

As a Restraint and Guide

U-bolts can function very well as a tube or pipe restraint. This means that they keep piping from moving, banging into other structures, and wearing down.

However, restraining pipes is about quite pinning them down. In some applications, simply holding down piping can cause corrosion at the purpose where pressure plays a major role. When used as a guide, the U-bolt regulates and controls movement without pressing vibrations into a concentrated point. This suggests pipes can move axially, or through the pipe restraint, but won’t bounce or vibrate up and down.

For Shipping

U bolts also can be used for keeping pipes snug during shipping. Instead of letting pipes soup up and down and break, the U-bolt can restrain pipes while adding a buffer between the pipes and other metals.

For Elevating Pipes

Another major use of U-bolts is for hanging pipes. Gravity is often technical on piping projects, and therefore the wrong setup can cause corrosion and falling objects. By securing a U-bolt to an overhead structure, beam, or ceiling, you will limit vibrations and secure elevated pipes.

U-Bolt Manufacturing Process

How are the U-bolts made? There are several processes that are followed when it comes to manufacturing U-bolts.

Cold forging of the U-bolt starts with large steel wire rods, which are uncoiled and have different dimensions. The grade of steel for u-bolt manufacturing is standardized across the globe, consistent with the requirements of ISO 898‑1.

u bolt bending machine

Using u bolt bending machine, the steel is then cold forged into the proper shape. This is often basically where the steel is molded, while at temperature, by forcing it through a series of pressurized dies.

The tooling itself is often quite complex, containing up to 200 different parts with tolerances of hundredths of a millimetre. Once perfected, cold forging ensures bolts are often produced quickly, in large volumes, and with high uniformity.

For more complex u-bolt designs, which cannot be contoured through cold forging alone, some additional turning or drilling could also be necessary.

The turning process involves spinning the bolt at high speed, while steel is cut away to realize the specified shape and style. Drilling is often wont to make holes through the bolt. If required, some bolts can also have washers attached at this stage of the method.

Heat treatment may be a standard process for all bolts, which involves exposing the bolt to extreme temperatures so as to harden the steel.

Threading is typically applied before heat treatment, either by rolling or cutting, when the steel is softer. Rolling works very similarly to cold forging and involves running the bolt through a die to shape and mold the steel into threads. Cutting the u-bolt entails forming threads by cutting and removing steel bits.

Since heat treatment is designed to alter the properties of the steel to form it harder, it’s easier and less expensive to use threading beforehand. However, threading after heat treatment will directly result in better fatigue performance.

U-Bolt Surface Treatment

On top of those common core elements, U-bolt manufacturers can add protective coatings. These finishes protect against corrosion even more. Here are some common coatings or surface treatments for U-bolts:

Zinc Plating

Zinc plating entails adding zinc using a layer of electricity. It’s usually a thinner layer that works better for indoor applications.

Hot-dip galvanization

The Hot-dip galvanization method also entails adding zinc, but it’s more intricate coating. U-Bolt manufacturers dunk the bolt in molten zinc to make a bond, which makes the coating well-suited for corrosive environments like areas with high humidity or salt within the air.

Fluoropolymer (Xylan, Teflon, or PTFE) Coating for u-bolts

A fluoropolymer coating may be a mixture of elements that are immune to corrosion. The coating can delay in extreme hot and cold temperatures without cracking.

Thermoplastic Coating

The main advantage of adding a thermoplastic coating to U-bolts is that the added buffer between metals. Metal-on-metal contact can cause galvanic corrosion and result in broken structures of the metal. A thermoplastic coating is used for adding a protective neutral layer between the pipe and therefore the restraint.

The choice of U-bolt surface treatment is decided by the U-bolt’s application. Therefore the requirements of the customer. Often, the most concern for fasteners is corrosion resistance, and thus a zinc-plated coating applied through electrolytic treatment may be a common solution.

How to Measure U-Bolts

When it comes to determining the u-bolts dimensions, there are many different ways of achieving this goal. This step is quite vital because the bolts need to be of the right size for whichever application that you will put them to.

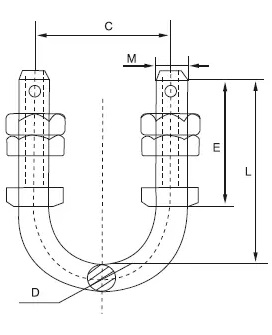

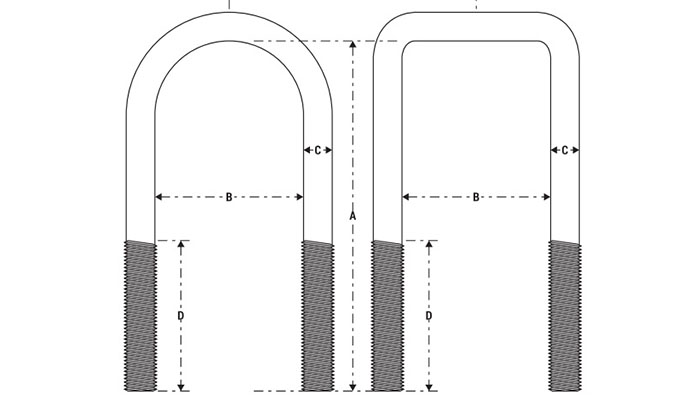

u bolt dimensions

There is no doubt that the sizes of u-bots tend to vary. There are large u-bolts while at the same time there are small u-bolts. U-bolts tend to be matched up with the dimensions of the pipes they’re meant to secure. Bolts can run anywhere from 1 / 4 of an in. to a full inch in rod size. and that they can hold piping as wide as 30 inches.

Check out the u-bolt size chart to know the different u-bolt dimensions.

Factors to Consider When Choosing U-Bolts

Which is the best U-bolt that you should buy for your use? Whichever application, here are the key factors that you should consider when buying U-bolts for sale:

Their purpose/application: The most critical role of U-bolts is to supply a clamping force to carry two components together.

U-bolt dimensions: U-bolts are measured supported the thread length, inside diameter, inside height, and thread size. U-bolts were originally measured using pipe add engineering to speak. Hence, a U-bolt would originally be characterized by the pipe’s size that it had been supporting.

U-bolts price: Like other commodities, you cannot avoid the issue of price. U-bolts are inexpensive. Custom pricing is usually dictated by quantity and quality. Contact the U-bolt manufacturer for clarification about the price.

Convenience: How convenient is it to use U-bolts? Generally, this refers to the ease of using this equipment. Not only are U-bolts tough and effective but also they’re available in different types of material. They also come in different strength grades to supply adequate clamping force. We cannot ignore the fact that U-bolts they’re also very easy to operate and they are versatile enough that they will apply to varied applications and industries. What’s more, is that there is zero material waste when it involves using U-bolts.

Physical definition: Several elements define the U-bolt: material type, rod diameter, inside diameter (between the legs), inside length, and thread dimensions.

U-Bolt Finish: U-bolts also can are available specialized finishes to face up better to the environments they’re intended to function in. As an example, for a U-bolt that’s getting to be used in humid or corrosive environments, a corrosion-resistant material like type 316 stainless steel or steel with a hot-dipped galvanized finish should get on the docket.

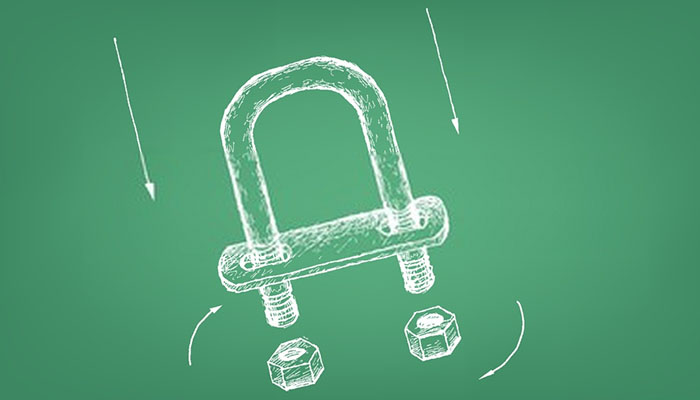

How to install U-Bolts-Step-By Step Guide

Of course, like all restraint, a U-bolt is merely nearly as good as its installation. Here is the way to install a U-bolt properly:

-Remove both nuts from all sides of the U-bolt

-Place the U-bolt around the pipe you’re attaching and thread the bolt’s ends through the holes in your support beam or structure.

-Thread all the nuts on each outer end of the bolt.

-Hand-tighten the nuts that are closest to the support beam.

-Tighten the outer nuts on each end of the U-bolt and use an influence tool or wrench to tighten the nuts.

If you’re using the U-bolt as a guide, confirm with the spacing to suit its specifications before tightening nuts.

Where to Buy U-Bolt in China: Powertelcom

Looking for the best U-bolts in China? Consider buying from Powertelcom. Whether you want leaf spring square u bolts, round u-bolts, or even custom u bolts. We will get them for you at affordable prices.

All you need to do is contact us for affordable u-bolts in China.

What is a U bolt?

U bolt is also named U-shaped bolt, U bolt clamp, or U bolt bracelet.

It is a curved bolt shaped like a “U”, with both ends threaded to attach nuts and washers.

How do U bolts work?

U Bolts, nuts, and washers are tightened together to provide clamping force and join the two parts together.

What is the application of U bolts?

U bolts are versatile in piping support, and they are also useful in building and construction applications like antenna section secured, wire cable fixation, roofing stability, and automotive components achieved.

What are the types of u bolts?

U bolts are commonly classified by bending shape and can be divided into round U bolts, semi-round U bolt, and square U bolt.

Reference:

What is a U bolt and how to measure it?- The Ultimate Guide