Pole line hardware exported to Peru

overhead transmission line fittings Manufacturer and Supplier

a reliable Partner

Are you finding a reliable manufacturer to supply pole line hardware and overhead transmission line fittings to Peru? Powertelcom is a good choice for you.

Peru has a big demand for pole line hardware. Powertelcom has exported its pole line hardware to Peru for over 10 years. The pole line hardware is a serious connection fitting to support the overhead line.

We can fully do according to Malaysia’s design,inspection,packing requirements. We know the Peru market, know the pole line hardware and know your needs, many customers from Peru choose Powertelcom as their pole line hardware manufacturer.

Experience work with electrical supplier in Peru

The pole line hardware is mainly used to connect and support the overhead power lines and transmission lines.

Our QC team knows how to control the quality. All the pole line hardware is made according to the standard ISO1461, the finish is hot-dip galvanized.

Peru uses the pole line hardware include as below:

Utility pole guy wires, cross arms, thimble clevis, suspension clamps, u bolt clamps, tension clamps, anchor rods, crossarm braces, and so on.

You can click the images for more details.

Still not finding what you’re looking for?

Check product categories or contact us for more informations.

Product catecategory

Why choose us?

Powertelcom is located in China, started in 2001. We have become a manufacturer of choice for many industries for our product accuracy, timely delivery, professionalism, excellent product quality, product customization, and latest technology use.

Years of Experience

Supply Peru since 2010, kinds of Molds for Peru.

OEM & ODM are available.

High quality

Automatic machines for cutting and welding improve quality and reliability.

QC test control makes every manufacturing process going smoothly.

Effective Logistics Management

Big production capacity and on-time delivery make your project done on time.

Support free warehousing service

Some Products Specifications

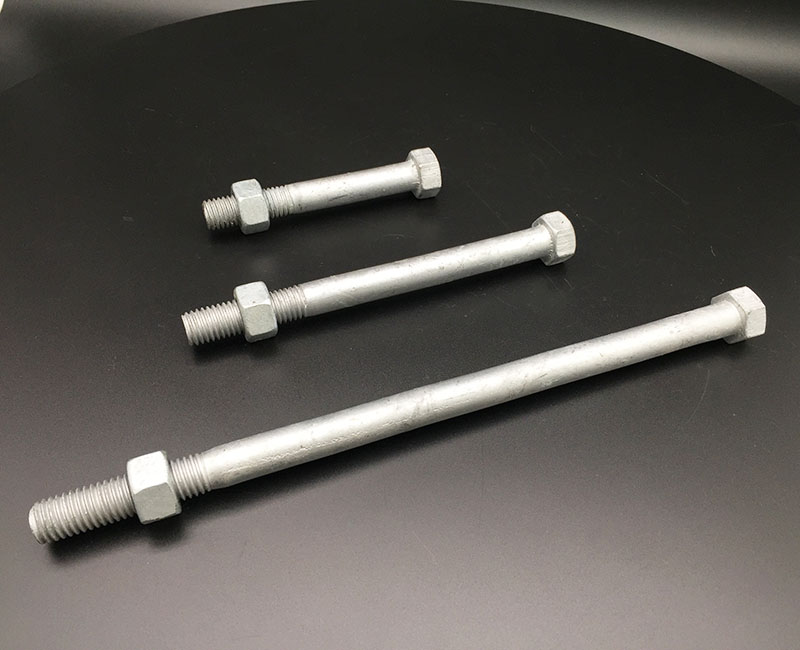

Hexagon head bolt and nut

Bolts and nuts are hot-dipped galvanized iron hexagon round head, size 300mmx16mm, 178mmx16mm, 114mmx16mm

SCHEDULE OF TECHNICAL PARTICULARS FOR BOLT & NUT 5/8X7”

| NO | Technical Speclfication | Requirements |

| 1 | Sample Required | Mandalory |

| 2 | Material | Mild Steel |

| 3 | Dimension | |

| a. Length of bolt | 178mm | |

| b. Length of thread | 50mm | |

| c. Thickness of hexagon round head | 12mm | |

| d. Thickness of nut | 15mm | |

| e. Width of bolt head & nut | 25mm | |

| F. Diameter of hole | 16mm | |

| 4 | Tolerance | 1% |

| 5 | The test results in accordance with standard | BS EN ISO 1429 |

Oval Eye Nut

The shape of this oval eye nut is oval, so that the other fittings can go through the vole hole to connect on to the line. The other end of the eye nut is a 5/8 thread which is used to assembled with the thimble eye nut.

Ball Eye Type

The ball eye has a round leg, the shape of the leg is round to connect with the socket clevis.

Turnbuckles with Eye and Hook

Turnbuckle can adjust its body length. When both sides of the turnbuckle move inside, the total body will be shorter and shorter. The turnbuckle is connected with the steel wire to make the pole concrete stable.

Thimble eye nut

The thimble eye nut is similar functional as the oval eye nut. There are two types: single thimble eye nut and double thimble eye nut. The single thimble eye nut has one curve on the head of the eye nut, while the other has two. The final treatment is hot-dip galvanized.

Thimble

The thimble is use one guy grip or stay set, to supply a curve to hole the steel wire. The thimble is very small, but the thimble performance a big function on the overhead line

Round pin anchor shackle

The U shackle is also called U cleis. We can make 70kn, 120kn breaking strength U clevis. The U shape is hot forget, not cold bend.

Frequently asked questions (FAQ)

For the different types of pole line hardware, there are different ways to do the hot-dip galvanization. For the electrical cross arm, alley arm, the manufacturer does the hot-dip galvanization at a big bow, the liquid temperature was controlled very well. And the consist element was settled according to a certain percent. For the casting part like socket clevis and pole top bracket, there is a different element consist to do the hot-dip galvanization. The hot forget is to heat the iron to a high temperature. When the iron body then red, the pushing machine will press it to the shape. In this way, the iron construction didn’t change. The cold bend is easier to do and saves the labor cost, it just bends the rod from the original condition, So the bent rod is easy to be broken when used on the overhead line. The manufacturer usually charges the tooling, if you don’t accept our present power fitting type. The manufacturer will make new tooling based on your design, and the new tooling belongs to you. The manufacturer just helps you to take care of the tooling in our factory. If you have paid for it, the manufacturer can also refund you the tooling cost if you ordered a certain quantity. Yes, of course. It’s a necessary step to confirm the sample before mass production. If the type of pole line hardware you required is in stock, the customer will only burden the express cost and have the sample for free. If you need to make new samples according to your drawing, you should charge the sample cost. Only T/T and L/C are acceptable, OA is not. If the pole line hardware you required is in stock, the goods will be shipped immediately after you pay. If there is no stock for your required, 20 days are needed to make 1*20 containers and confirm further whether it is needed to make new tooling for it.How to make hot-dip galvanization perfect?

What’s the difference between the cold bend process and the hot forget?

Who will charge if making a new design?

Can we get a sample before placing an order?

What’s the payment item?

What is the delivery time for the power fitting?